5-axis CNC Machining Services

Start A New CNC Quote

5 Axis Machining

With RapidDirect

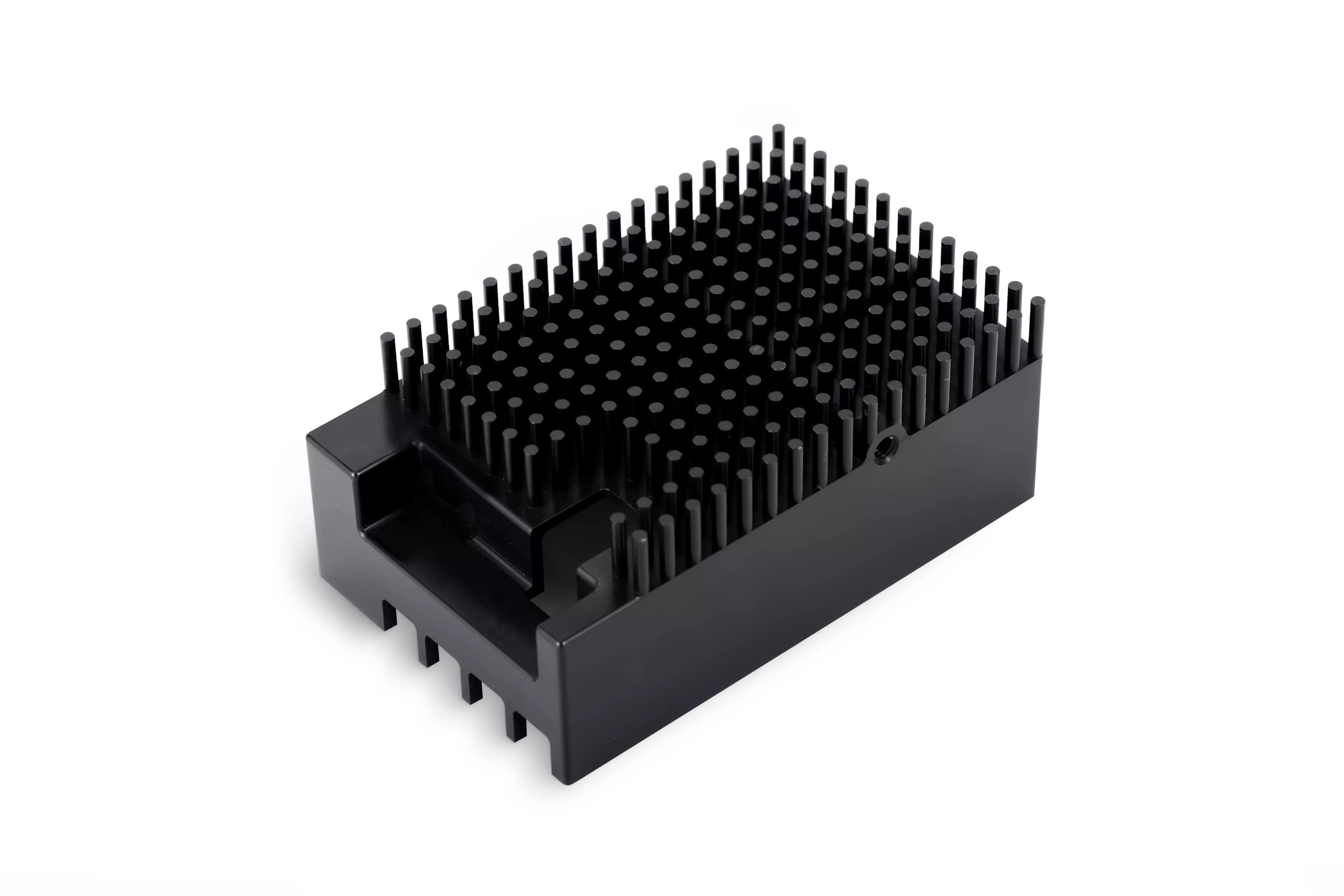

RapidDirect’s 5-axis machining services offer unparallel speed and flexibility. With an extensive range of advanced 5-axis CNC machines and a long list of materials, RapidDirect has the capability to deliver the best 5-axis machined parts.

Our experienced team and manufacturing capabilities help rapidly design and fabricate complex, time-sensitive components. With world-class equipment, expertise, and experience, RapidDirect uses two outstanding setups to provide precise, complex parts.

What is 5-axis Machining?

5-axis CNC machining is an advanced manufacturing process that allows the cutting tool to move simultaneously across five different axes. This capability is essential for producing complex, high-precision parts with greater efficiency and fewer setups. Industries like aerospace, automotive, and medical device manufacturing rely on 5-axis machining services for intricate components that require extreme accuracy.

5-axis VS. 3-axis Machining

In CNC machining, selecting between 3-axis and 5-axis systems greatly affects production capabilities. 3-axis machining operates along the X, Y, and Z axes, making it suitable for simpler parts with flat surfaces, commonly used in industries like automotive, construction, and aerospace due to its efficiency and lower costs.

In contrast, 5-axis machining adds two rotational axes, allowing the tool to cut from multiple angles, which is ideal for creating highly intricate parts with complex geometries. This system is preferred in fields such as aerospace, medical, and advanced automotive manufacturing, where precision and tighter tolerances are critical.

Although 5-axis systems involve higher upfront costs, they offer greater production efficiency by reducing the need for multiple setups and lowering the chances of human error. Ultimately, 3-axis machines are ideal for basic designs, while 5-axis machines excel in producing complex components requiring greater accuracy.

Materials for Custom 5-axis CNC Machining

Your 5-axis milling services are compatible with a wide array of materials, ranging from metals to plastics. Depending on your applications, you can choose from the over 50 production-grade materials we offer at RapidDirect. See our list of 5-axis CNC machining materials. You can also contact us to discuss your unique requirements.

Aluminum is lightweight yet strong, with excellent machinability and corrosion resistance. Ideal for aerospace and automotive parts.

Alloys

Aluminum 6061, 6061-T6

Aluminum 2024

Aluminum 5052

Aluminum 5083

Aluminum 6063

Aluminum 6082

Aluminum 7075, 7075-T6

Aluminum ADC12 (A380)

LEARN MORECopper is known for its superior electrical conductivity and thermal properties, making it perfect for electrical components and heat exchangers.

Alloys

Copper C101(T2)

Copper C103(T1)

Copper C103(TU2)

Copper C110(TU0)

Beryllium Copper

Brass is durable and has a low friction coefficient, which makes it suitable for fittings, tools, and musical instruments that require precision.

Alloys

Brass C27400

Brass C28000

Brass C36000

Bronze is highly resistant to corrosion and metal fatigue, favored for bearings, bushings, and marine hardware.

Alloys

Tin Bronze

Steel is an alloy with high tensile strength and durability, commonly used in construction and automotive industries for its robustness.

Alloys

Steel 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36

Die steel

Alloy steel

Chisel tool steel

Spring steel

High speed steel

Cold rolled steel

Bearing steel

SPCC

Stainless steel is renowned for its corrosion resistance, making it a prime choice for medical devices and food processing equipment.

Alloys

Stainless Steel SUS201

Stainless Steel SUS303

Stainless Steel SUS 304

Stainless Steel SUS316

Stainless Steel SUS316L

Stainless Steel SUS420

Stainless Steel SUS430

Stainless Steel SUS431

Stainless Steel SUS440C

Stainless Steel SUS630/17-4PH

Stainless Steel AISI 304

Magnesium is the lightest structural metal, offering high strength-to-weight ratios, perfect for automotive and aerospace applications where weight is critical.

Alloys

Magnesium Alloy AZ31B

Magnesium Alloy AZ91D

Titanium boasts the highest strength-to-density ratio among metals, highly resistant to corrosion and fatigue, ideal for aerospace, medical, and marine applications.

Alloys

Titanium Alloy TA1

Titanium Alloy TA2

Titanium Alloy TC4/Ti-6Al 4V

ABS is strong, durable, and offers good resistance to heat and impact. It’s preferred for automotive components and consumer goods.

ABS Beige(Natural)

ABS Black

ABS Black Antistatic

ABS Milky White

ABS+PC Black

ABS+PC White

Polycarbonate is extremely durable and has high impact resistance, along with excellent clarity, used for bullet-proof glass and protective gear.

PC Black

PC Transparent

PC White

PC Yellowish White

PC+GF30 Black

PMMA, or acrylic, is known for its crystal clarity and weather resistance, making it ideal for outdoor fixtures and display cases.

PMMA Black

PMMA Transparent

PMMA White

POM is strong, with a low friction surface and good dimensional stability, perfect for precision parts in mechanical applications.

Dark brown (coffee) POM 100AF

POM Black

POM Blue

POM White

Nylon is versatile, strong, and wears well against friction, commonly used for gears, bearings, and other wear-resistant surfaces.

PA(Nylon) Blue

PA6 (Nylon)+GF15 Black

PA6 (Nylon)+GF30 Black

PA66 (Nylon) Beige(Natural)

PA66 (Nylon) Black

Polyethylene is lightweight and has high resistance to impact, widely used in packaging and containers.

PE Black

PE White

PEEK is renowned for its high temperature resistance and strength, often used in aerospace and medical implant manufacturing.

PEEK Beige(Natural)

PEEK Black

Polypropylene is tough, has excellent chemical resistance, and is used for automotive parts, containers, and in packaging.

PP Black

PP White

PP+GF30 Black

HDPE is known for its high strength-to-density ratio, resistance to impacts, and is used in making bottles and corrosion-resistant piping.

HDPE Black

HDPE White

HIPS is easy to machine and offers good dimensional stability and impact resistance, suitable for prototyping and modeling.

HIPS Board White

LDPE is soft, flexible, and used in applications where heat sealing is required, such as in tubing and plastic bags.

LDPE White

PBT is a strong, rigid plastic that is heat resistant and commonly used in electrical components and casings.

PBT Black

PBT Milky White(Natural)

PPA offers high heat resistance and stiffness, ideal for automotive and electrical applications that require durability at high temperatures.

PAI has exceptional thermal and chemical stability, used in high-performance parts in aerospace and automotive sectors.

PAI Brown

PET is strong, resistant to moisture and chemicals, and widely used in food containers and textile fibers.

PET Black

PET White

PET+GF30 Black

PET+GF30 White

PPS features outstanding chemical and heat resistance, suitable for automotive and aerospace components.

PPS Black

PPS White

PPS+GF30 Black

PPS+GF30 White

Polystyrene is lightweight and easy to machine, used for models, prototypes, and low-strength applications.

PS Transparent

PVC is robust, cheap, and has good chemical resistance, used in plumbing, medical devices, and cables.

PVC Grey

PTFE is known for its outstanding chemical resistance and low friction, making it perfect for non-stick coatings and gaskets.

Teflon (PTFE) Black

Teflon (PTFE) White

UPE has extremely long chains, resulting in a very tough material, ideal for high-abrasion applications like lining chutes.

UPE Black

UPE White

Bakelite is heat resistant and electrically non-conductive, perfect for electrical insulators and radio and telephone casings.

Bakelite Black

Bakelite Orange

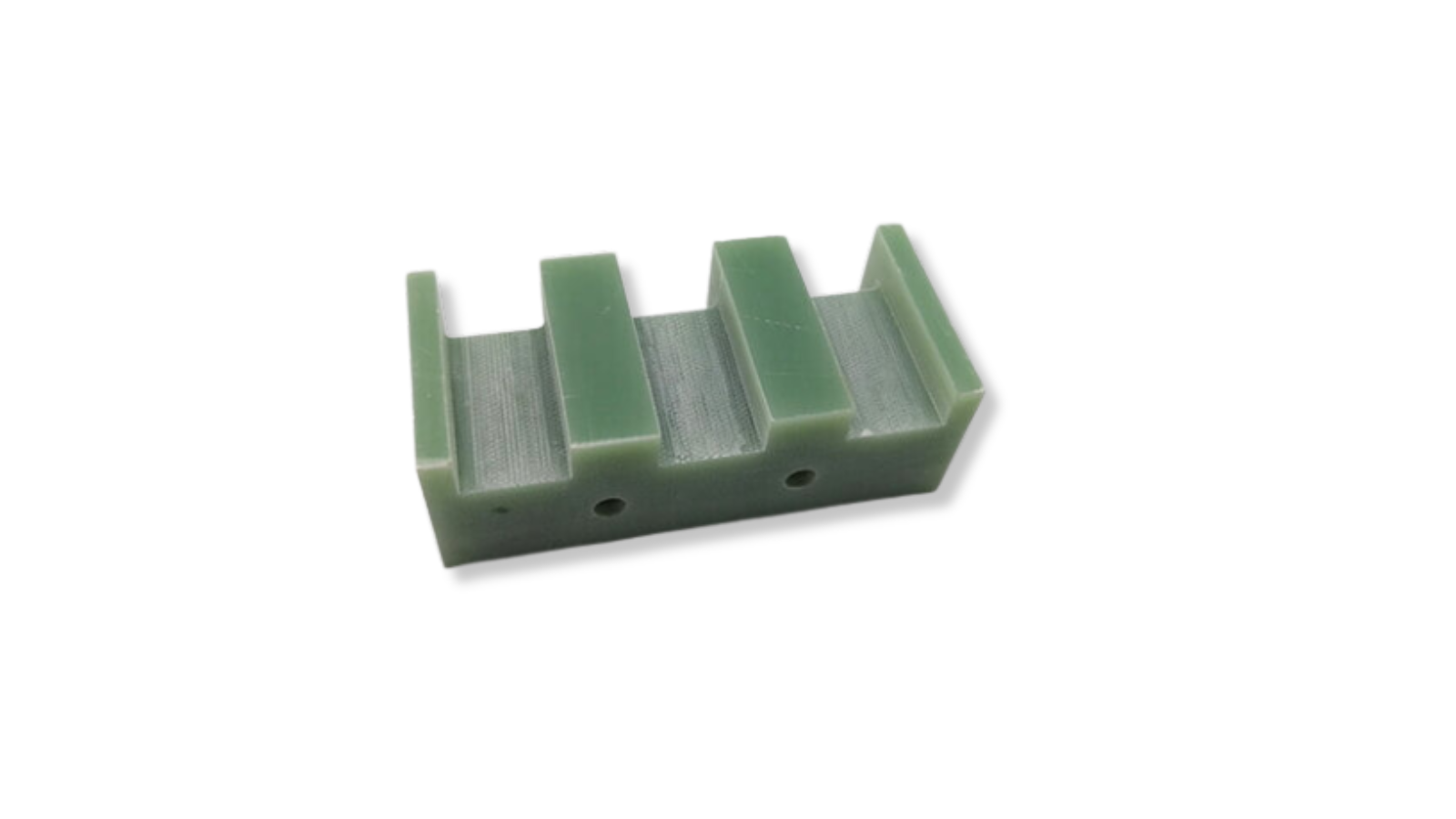

FR-4 is a flame-resistant material, primarily used in the electronics industry for circuit boards and insulators.

FR-4 Aqua Green

FR-4 Yellow

Surface Finishes for 5 Axis CNC Machining

With an extensive list of surface finishes available, RapidDirect can enhance the surface quality of your 5-axis machined parts. Applying these finishes help improve the appearance of the components, their surface roughness, hardness, corrosion resistance, and more. They also hide visible tool marks on the products’ surfaces.

Polishing

5-Axis CNC

Machining Capabilities

Our ISO 9001 certification shows that we fabricate 5-axis milled parts to meet the tightest tolerance requirements. Our standard tolerance for CNC-milled plastics is ISO-2768-m and ISO-2768-f for metals. Get high-quality and precise complex parts with top-notch dimensional stability.

| Description | |

|---|---|

| Maximum Part Size | 4000×1500×600 mm |

| Minimum Part Size | 5 x 5 x 5 mm |

| General Tolerances | Within ±0.002 mm |

| Lead Time | For standard operations, lead times can be as short as 2-3 days, while more complex projects might require up to 2 weeks. |

5 Axis CNC Machining

Design Guidelines

| Recommended Size | |

|---|---|

| Minimum Feature Size | Minimum feature size should be no less than 0.5 mm in width or depth to ensure structural integrity. |

| Linear Dimension | Maintain a precision within ±0.005 mm for linear dimensions to ensure accuracy across the machined part. |

| Hole Diameters (not reamed) | Holes can be machined with diameters starting from 1 mm up to 40 mm without reaming for precision sizing. |

| Shaft Diameters | Shaft diameters should range from 2 mm to 300 mm, considering the tool accessibility and torque requirements. |

| Threads and Tapped Holes | Threads from M2 to M24 can be machined. Ensure to provide adequate relief at the bottom of tapped holes. |

| Text | Minimum text height of 1.5 mm with a depth of 0.5 mm for clarity after machining. |

RapidDirect 5-axis Machine Shop

Check out our incredible line of well-functioning 5-axis machining centers ranging from the best 5-axis horizontal machining centers to top-notch vertical machining centers. With a fleet of 9 sets of 5-axis CNC machines, we have the capacity and capability to handle large-scale production while maintaining precision and efficiency. These advanced machines, combined with our skilled technicians, allow us to meet diverse manufacturing needs across various industries. Trust our services to deliver results that perfectly suit your requirements.

Contact us for a free quote or more information on RapidDirect’s 5-Axis CNC machining services. We offer custom solutions for precise, durable, and strong parts in a variety of shapes and sizes to meet your project needs.

700+

Sets of Machine

120+

Countries Shipped

20,000+

Customers Served

Start Your

CNC Machining Project

Kickstart your project with our easy-to-use online quoting platform. Upload a CAD file to receive instantly quotes, lead time, and DFM details for your CNC components. Specializing in CNC machining for metals and plastics, we provide adaptive production and shipping solutions to align with your product development needs.

Why

Choose Us

Parts

Experience unparalleled precision in each undertaking. Our advanced milling processes ensure components adhere to tight tolerances, as tight as ±0.01mm, resulting in seamless assembly and operational excellence.

Time

Accelerate your manufacturing cycle. RapidDirect domestic workshops and state-of-the-art machinery guarantee fast turnaround times, helping businesses maintain momentum and meet critical deadlines.

Support

No matter you whenever and whereever, navigate your CNC milling projects with confidence. Our seasoned specialists offer insightful guidance at every step, maximizing design optimization and output quality.

Success Stories of

5 Axis CNC Machining Services

Simultaneous 5 Axis vs 3+2 Axis CNC Machining

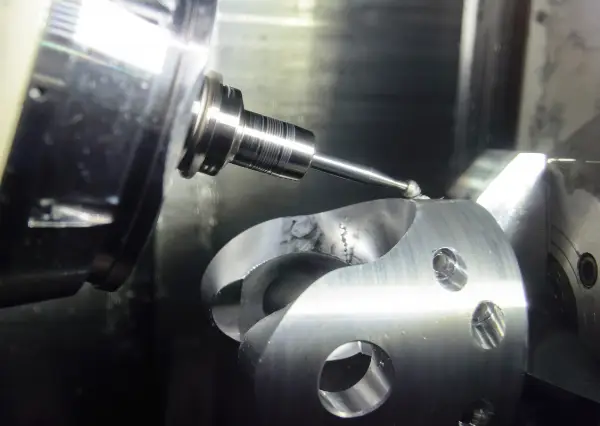

Simultaneous 5-Axis Machining

Fast, effective, and continuous 5-axis CNC machining with improved transitioning and surface quality. Here, we use 5-axis machining center that can continuously adjust the movements on all five axes without stopping. Our 5-axis CNC machining has intelligent functionalities to ensure efficient continuous processes and transitions.

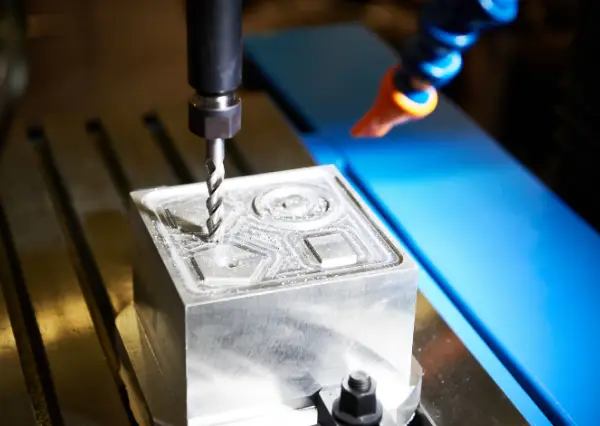

3+2 Axis Machining

Take advantage of the optimal 3+2 axis machining technology for your unique applications. The process keeps the part fixed in a specific orientation to allow the usual 3-axis machining process. Our 3+2 axis machining uses shorter, more rigid cutting tools to offer your parts better dimensional stability. Get complex CNC machined parts with tight tolerances at lower costs and cycle time.

Trunnion-Style vs Swivel-Rotate-Style 5-Axis Machining

Trunnion-style machining centers

Feature a fixed table and a spindle that moves and rotates along two axes. This design allows for the machining of complex parts from multiple angles in a single setup, making it highly efficient for heavy or larger workpieces due to the stable support from the table.

Swivel-Rotate-Style machining

Also known as a table-table configuration, involves the part being affixed to a table that rotates and tilts, while the spindle remains in a fixed position. This style is particularly advantageous for intricate parts that require high precision, as it offers excellent accessibility to various part features and can handle smaller, more delicate components effectively.

Advantages of 5 Axis CNC Machining

5-axis CNC machining offers significant advantages over traditional 3-axis machining, making it a valuable choice for complex and precision-demanding projects.

- Complex Geometries: Allows for the machining of intricate designs and complex shapes from any angle, reducing the need for multiple setups.

- Enhanced Accuracy: Minimizes handling errors associated with multiple setups, improving the overall accuracy of the finished product.

- Improved Surface Finish: The tool can maintain an optimal angle relative to the surface, enhancing the quality of the surface finish and reducing the need for secondary finishing operations.

- Use of Shorter Cutting Tools: Enables closer positioning of the tool to the workpiece, which reduces tool deflection and vibration, leading to more precise cuts.

- Increased Productivity: Reduces overall production time by combining what traditionally requires several machine setups into a single setup.

- Material Conservation: Efficient tool paths and advanced control minimize material waste, which is especially beneficial when working with expensive materials.

Applications of 5 Axis CNC Machining

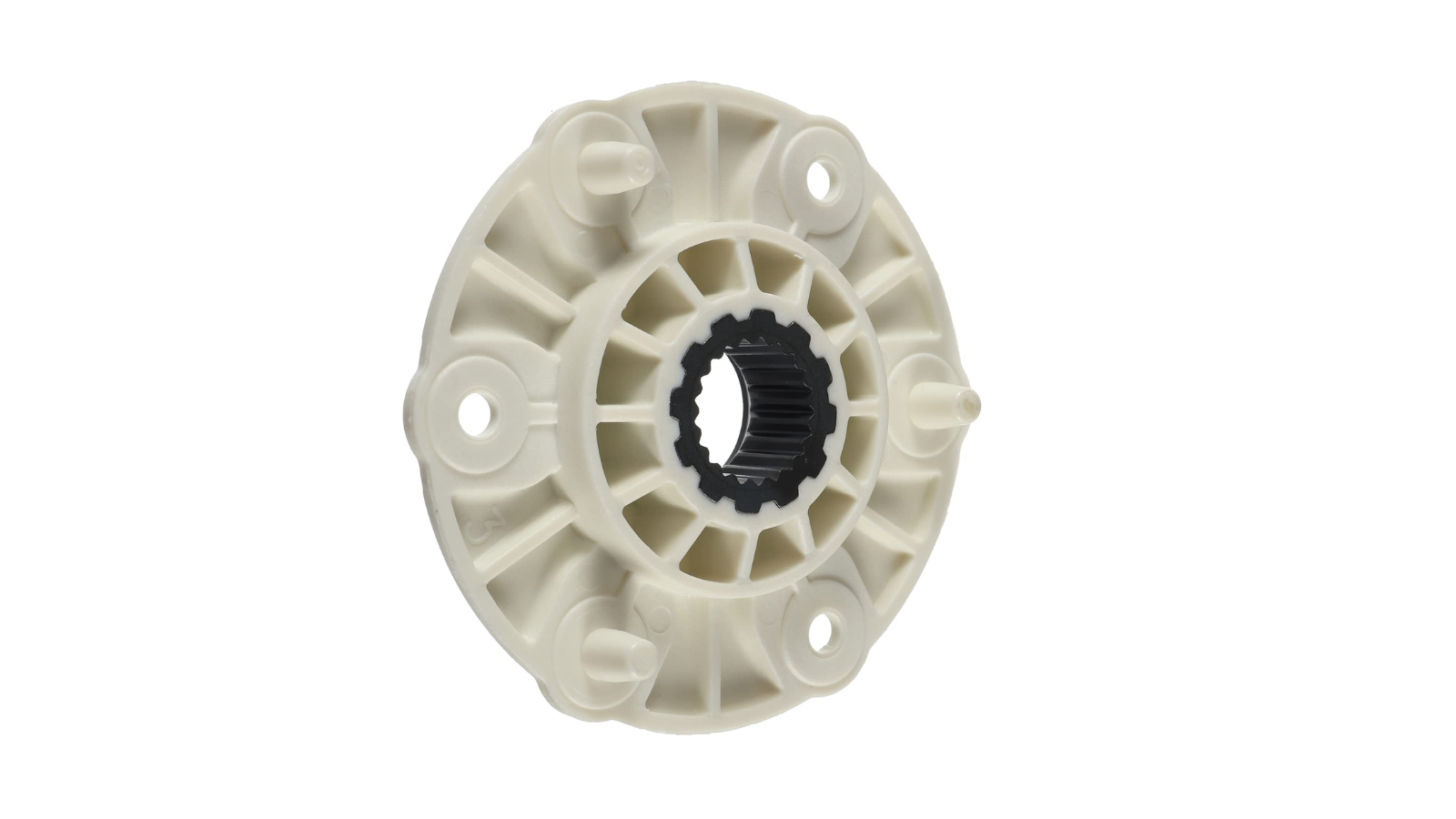

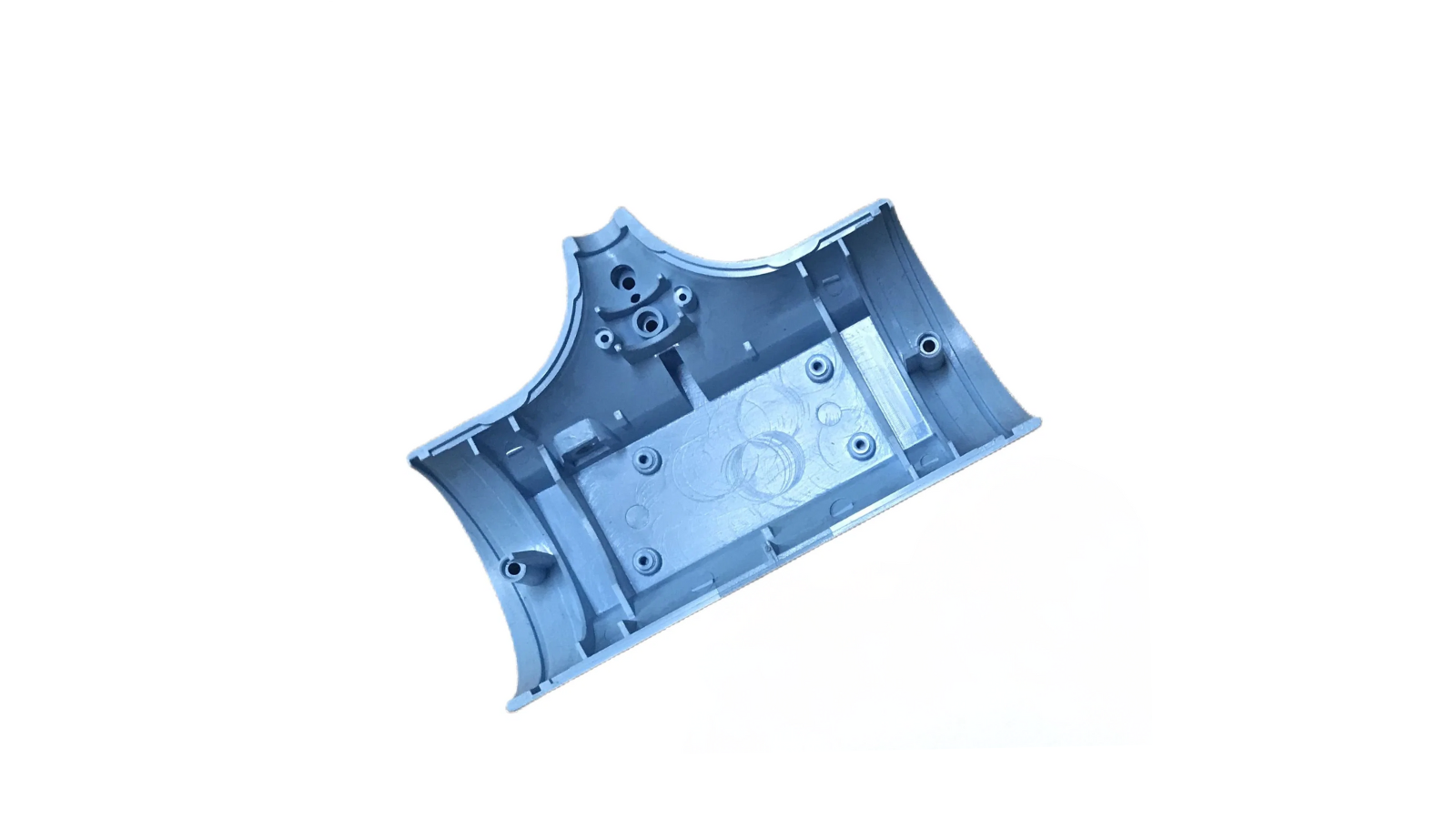

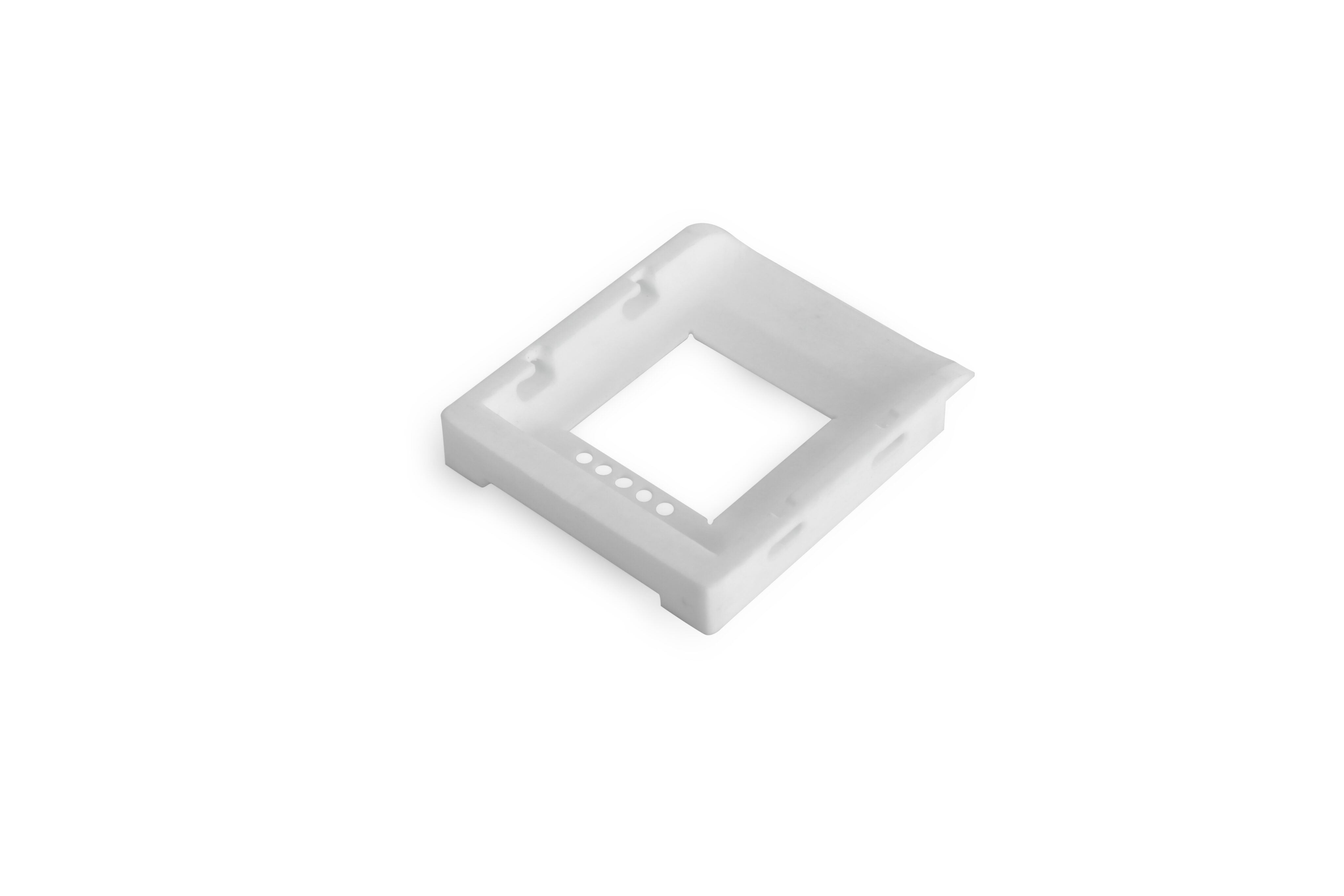

5-axis CNC machining is extensively utilized for its versatility in creating various part types across multiple industries.

- Aerospace Components: Crafting airframe structures and engine parts that require complex contours and must withstand extreme conditions. Examples include turbine disks, compressor blades, and swivel bearings.

- Automotive Parts: Producing transmission gears, engine mounts, and complex hub assemblies. These parts often involve intricate features and deep pocket cuts, which 5-axis CNC machining handles efficiently.

- Medical Implants: Manufacturing bespoke medical implants such as hip joints and cranial plates. These require highly customized shapes and smooth finishes to match patient anatomy.

- Die and Mold Making: Creating complex molds, dies, and fixtures that are crucial for the mass production of other products. This includes injection molds and stamping dies with detailed features and tight tolerances.

- Marine Parts: Building parts for boats and other marine vehicles, such as propellers and hull components. These parts often have complex designs and require precise machining to ensure performance and durability in harsh environments.

- Energy Sector Components: Machining parts used in power generation equipment, such as wind turbine hubs and solar panel frames. These require high precision to ensure efficiency and long-term reliability.

FAQs

Yes, 5-axis CNC machining is renowned for its ability to achieve exceptionally tight tolerances. It can typically maintain precision within ±0.005 mm. This high level of accuracy is due to the machine’s capability to access five sides of a part in a single setup, reducing the number of setups required and minimizing errors associated with repositioning. The simultaneous movement along five axes allows for closer tool paths, ensuring precise adherence to design specifications, especially for complex geometries.

The cost of 5-axis CNC milling services can vary widely based on several factors such as the complexity of the part, the type of material used, and the required precision. Generally, prices might range from $75 to $250 per hour depending on these variables. For a specific quote, it’s best to provide detailed drawings and specify material requirements on RapidDirect online platform so that a more accurate estimation can be calculated. Remember, while 5-axis machining might have a higher hourly rate, it often reduces the total production time and number of setups needed.

Opt for 5-axis CNC machining when manufacturing parts with complex geometries, intricate details, or when high precision is critical. This technology is ideal for parts that require machining from multiple sides in a single setup or where multiple tool angles are necessary to achieve the design. Industries such as aerospace, medical, and automotive, where the geometrical complexities and tight tolerances are common, significantly benefit from 5-axis machining. It is also preferable when aiming to reduce lead times and improve surface finishes without compromising on detail.

The main difference between 5-axis and 3-axis machining lies in their respective capabilities and the complexity of parts they can handle. 3-axis machining operates along three axes (X, Y, and Z), suitable for parts with relatively simple geometries. It typically requires multiple setups and repositioning to reach all sides of the part. Conversely, 5-axis machining adds two additional rotational axes, allowing the cutting tool to approach the part from virtually any direction. This capability makes it ideal for complex shapes, reducing setup times and improving precision by minimizing handling.

CNC Machining

Resources

now, for free