Custom Online

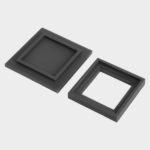

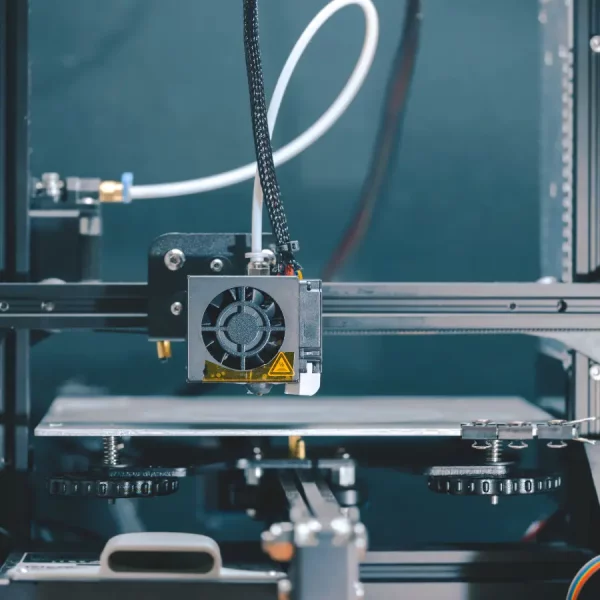

3D Printing Services

Get instant online quotes for 3D printed parts in both plastics and metals. Order high resolution rapid prototypes and production parts with precision.

- Tolerances as fine as ±0.2 mm.

- ISO 9001:2015, ISO 13485, ISO14001:2015, IATF 16949:2016 certified

- Lead time as fast as 1 day

Uploading

Max. file size: ≤15MB

Custom Online 3D Printing Services

Start A 3D Printing Quote

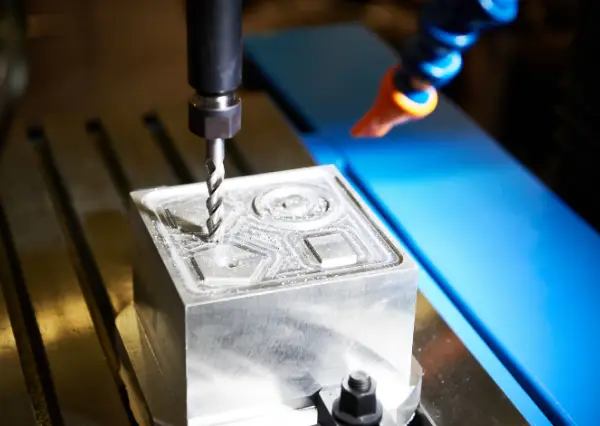

3D Printing Services for Custom Prints

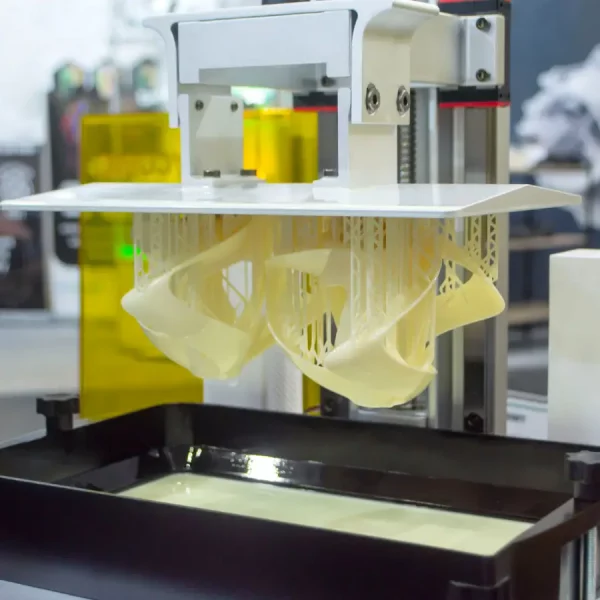

SLA

SLA utilizes a laser to cure liquid resin into solid parts with high precision and smooth surfaces. Ideal for detailed prototypes and intricate designs.

HP MJF

HP MJF uses a fusing agent and heat to create strong, functional parts with fine details and excellent mechanical properties.

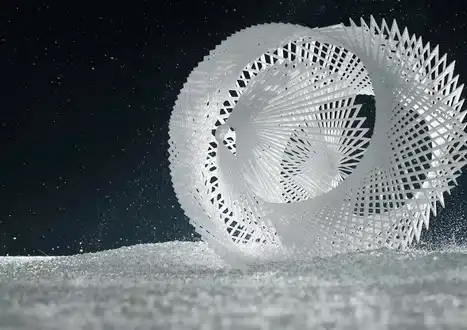

SLS

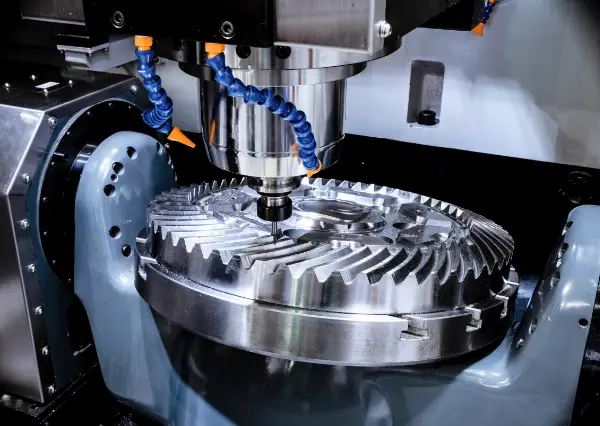

SLS fuses powdered material layer by layer using a laser, producing robust and durable parts. It’s excellent for complex geometries and end-use applications.

SLM

SLM melts metal powders with a laser to create high-strength, intricate metal parts. This process is ideal for aerospace, medical, and industrial applications.

How Does RapidDirect 3D Printing Services Work

RapidDirect operates a network of 300+ 3D print shops, using layer-by-layer printing to create both complex prototypes and large runs of production parts. We inspect each component for dimensional accuracy and visual quality, guaranteeing that every custom 3D printed part meets your exact requirements and maintains consistency across all projects.

300+

Sets of Machine

120+

Countries Shipped

20,000+

Customers Served

How Does RapidDirect 3D Printing Services Work

RapidDirect operates a network of 300+ 3D print shops, using layer-by-layer printing to create both complex prototypes and large runs of production parts. We inspect each component for dimensional accuracy and visual quality, guaranteeing that every custom 3D printed part meets your exact requirements and maintains consistency across all projects.

300+

Machines Set

120+

Countries Shipped

20,000+

Customers Served

3D Printing Materials

Our material selection includes plastic and metal options like ABS, PA (Nylon), Aluminum, and Stainless Steel, suitable for various industrial custom 3D printing projects. If you have unique material requirements, simply choose ‘Other’ on our quote configuration page. We’re committed to sourcing exactly what you need.

- Aluminium

- Stainless Steel

- ABS

- PA (Nylon)

Aluminium

Lightweight, strong, and naturally resistant to corrosion, aluminum is ideal for 3D printing in aerospace and automotive applications. Its excellent strength-to-weight ratio makes it perfect for parts that need durability without adding excess weight.

| Color: | Silver |

| Subtypes: | Stainless Steel 316L Silver Grey |

| Price: | $$$ |

| Lead Time: | About 6 business days |

Stainless Steel

Highly durable, corrosion-resistant, and heat-tolerant, stainless steel is great for both functional parts and intricate, high-strength components. It's commonly used in industries requiring robustness, such as aerospace, automotive, and medical devices.

| Color: | Silver |

| Subtypes: | Stainless Steel 316L Silver Grey |

| Price: | $$$ |

| Lead Time: | About 6 business days |

ABS

Known for its strength, durability, and resistance to heat and impact, ABS is a popular choice for 3D printing functional prototypes and end-use parts. It's widely used in automotive, consumer goods, and industrial applications due to its toughness and versatility.

| Color: | Yellow Black Creamy White |

| Subtypes: | ABS-Like Resin Black ABS-Like Resin Creamy White |

| Price: | $ |

| Lead Time: | About 4 business days |

PA (Nylon)

Flexible, tough, and resistant to wear and abrasion, nylon is perfect for parts that need to withstand heavy use. It's lightweight, has a low friction coefficient, and is often used in industrial applications, gears, and mechanical components.

| Color: | Black White |

| Subtypes: | Nylon Black (High Temperature Resistant 110 ℃) Nylon Black (High Temperature Resistant 140 ℃) Nylon PA12 White Nylon PA12-Black |

| Price: | $$ |

| Lead Time: | About 5 business days |

Aluminum

Lightweight yet strong, aluminum is favored for its excellent strength-to-weight ratio and natural corrosion resistance. Ideal for aerospace and automotive applications.

Aluminium (AISi10Mg) Silver Grey

Highly durable and resistant to corrosion and heat, stainless steel is suitable for both functional parts and detailed, high-strength components in demanding environments.

Stainless Steel 316L Silver Grey

A strong, durable plastic popular for its high resistance to heat and impact. Ideal for functional prototypes and end-use parts.

ABS-Like Resin Black

ABS-Like Resin Creamy White

ABS-Like Resin Yellow (High Toughness )

ABS-Like ResinTranslucent

ABS-Like ResinTransparent

Known for its flexibility and toughness, nylon is perfect for parts requiring high resistance to wear and abrasion. It’s also lightweight and has a low friction coefficient.

Nylon Black (High Temperature Resistant 110 ℃)

Nylon PA12 White

Nylon PA12-Black

3D Printing Post Processing

Post-processing enhances the appearance and functionality of 3D prints, providing a smooth finish, vibrant colors, or added durability. It’s ideal for visible or functional components but may be unnecessary for rough prototypes or internal parts where aesthetics are not a priority.

Polishing

Reduces roughness for a smoother, more visually pleasing surface on visible parts.

RapidDirect

3D Printing Solutions

3D Printing

Start your project with our fast 3D printing service. Ideal for creating detailed prototypes and custom parts quickly, we use advanced technologies to deliver high-quality, high-resolution prints with precise tolerances.

- Iterate and refine your designs rapidly to ensure perfect results.

Vacuum Casting

Our urethane casting service bridges the gap between prototyping and mass production. Perfect for low to medium-volume production, creating durable, high-quality parts with excellent surface finish and detail.

- For market testing and initial product launches.

Injection Molding

For large-scale production needs, our injection molding service is the optimal choice. It is capable of producing high volumes of parts efficiently, maintaining consistent quality and precision.

- Cost-effective process for mass production.

RapidDirect

3D Printing Capabilities

We provide a comprehensive overview of each 3D printing process’s unique standards, aiding in informed decisions for your printing needs.

| SLA | MJF | SLS | SLM | |

|---|---|---|---|---|

| Min. Wall Thickness | 0.6mm for unsupported walls, 0.4mm for supported walls on both sides | At least 1mm thick; avoid overly thick walls | From 0.7mm (PA 12) to 2.0mm (carbon-filled polyamide) | 0.8 mm |

| Layer Height | 25 µm to 100µm | Around 80µm | 100–120 microns | 30 – 50μm |

| Max. Build Size | 1400x700x500mm | 264x343x348mm | 380x280x380mm | 320x320x400mm |

| Dimension Tolerance | ±0.2mm (For >100mm, apply 0.15%) | ±0.2mm (For >100mm, apply 0.25%) | ± 0.3mm (For >100mm, apply 0.35%) | ±0.2mm (For >100mm, apply 0.25%) |

| Standard Lead Time | 4 business days | 5 business days | 6 business days | 6 business days |

Online 3D Printing Services

Need 3D printed parts quickly? Start effortlessly by uploading your 3D model files; our platform supports formats like [.STP], [.STEP], and [.STL], ensuring seamless integration. Receive an instant, custom quote as our algorithms assess your design for optimal manufacturability.

Choose from a vast selection of materials and finishes, guided by our experts to balance cost, functionality, and aesthetics. Utilizing high-resolution 3D printers, we deliver your vision with exceptional accuracy. Each print is rigorously inspected to meet your specifications. Enjoy rapid delivery—receive your high-quality prints as soon as the next day.

3D Printing

for Various Industries

Our services cover automotive, aerospace, and healthcare industries, providing customized solutions for each.

Success Stories of

3D PrintingProjects

Why

Choose Us

3D Prints

Advanced materials, cutting-edge technology, and stringent quality control processes. This commitment results in quality product durability and precision, minimizing rework and enhancing your project’s success.

Time

Streamlined processes and state-of-the-art equipment, addressing your urgent needs by delivering high-quality 3D printed items quickly. This efficiency reduces wait times, enhancing your project’s pace and productivity.

Experts

We have team of experienced engineering experts providing personalized guidance for every project. Resolve complex design challenges, enhancing print success and customer satisfaction, according to your unique specifications.

Ultimate Guide to 3D Printing

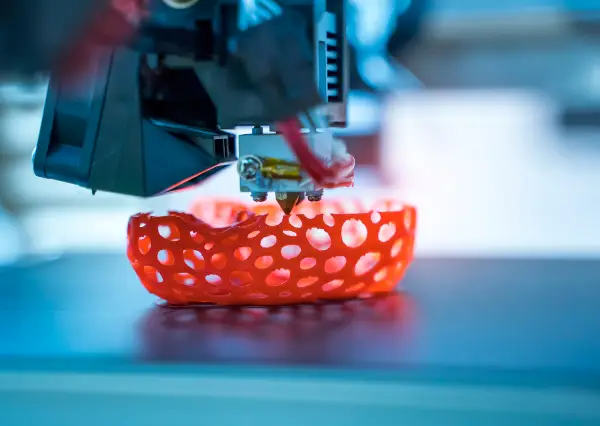

What’s 3D Printing?

3D printing, also known as additive manufacturing, is a revolutionary technology that creates three-dimensional objects from digital files. This process involves adding material layer by layer until the final object is formed. Unlike traditional manufacturing methods, which often involve subtracting material from a larger block, 3D printing allows for the creation of complex geometries and intricate details with minimal waste. It’s used in various industries, from prototyping and product development to medical implants and aerospace components. 3D printing offers significant advantages in customization, speed, and cost-effectiveness, making it an essential tool in modern manufacturing.

Advantages of 3D Printing

3D printing has many advantages over traditional methods:

- Customization: Easily create custom items without added cost or complexity—perfect for personalized or bespoke solutions.

- Complex Geometries: Make intricate designs and structures that are impossible with traditional manufacturing, enabling advanced features.

- Reduced Waste: Only the material needed is used, cutting down waste compared to subtractive methods.

- Rapid Prototyping: Quickly create prototypes to test design, fit, and function, speeding up development.

- Cost-Effective for Small Runs: Ideal for low-volume production, saving on tooling and molds.

- Speed to Market: Cut production lead times, enabling faster iteration and quicker product launch.

Custom 3D Printing Applications

3D printing offers a wide range of applications for different types of parts:

- Prototypes: Quickly turn design concepts into functional and visual prototypes.

- Custom Tools & Fixtures: Make production-specific tools and jigs that boost efficiency.

- Medical Implants & Prosthetics: Create custom implants and prosthetics for improved fit and comfort.

- End-Use Parts: Produce ready-to-use parts for various applications.

- Architectural Models: Build detailed models for design and planning.

- Customized Consumer Goods: Create one-of-a-kind items like jewelry, phone cases, and home products.

- Educational Models: Make accurate models for research and teaching.

- Replacement Parts: Print rare or obsolete components for maintenance and repairs.

FAQs

3D printing can achieve remarkably high levels of accuracy, ensuring that your parts meet stringent specifications. At RapidDirect, our standard tolerance for 3D printing is ±0.1mm. However, the exact tolerance can vary depending on the complexity and design of your part. For highly detailed or intricate components, tolerances might need to be adjusted to ensure optimal results. To provide you with the most accurate assessment, you can upload your 2D design files through our platform. Our expert team will evaluate your design and determine the specific tolerances required to achieve the best possible outcome for your project.

The time required to 3D print parts depends on several key factors, including part size, height, complexity, and the chosen printing technology. Larger or more complex parts naturally take longer to print than smaller, simpler ones. At RapidDirect, we understand the importance of fast turnaround times. Leveraging advanced 3D printing technologies and efficient processes, we can complete many 3D printing projects in as little as one day. For precise time estimates tailored to your specific project, you can upload your design files, and our team will provide a detailed timeline based on your unique requirements.

It depends on the specifications of the 3D printer used. At RapidDirect, we offer a wide range of 3D printing machines to accommodate various sizes and requirements.

- Large Format FDM Printers: Capable of printing up to 36 x 24 x 26 inches, ideal for large parts and prototypes.

- Large SLA Printers: Can produce prints up to 29 x 25 x 21 inches, perfect for high-detail and smooth-surface applications.

- SLS Printers: Unfilled SLS machines have a maximum build dimension of 13 inches, while glass-filled SLS machines can handle up to 26 x 15 x 23 inches.

- Industrial Polyjet Printers: Offer a build area of up to 19 x 15 x 7 inches, suitable for high-resolution and multi-material prints.

This diverse selection ensures we can meet your project’s specific size and detail requirements.

At RapidDirect, we accept a variety of file formats to ensure compatibility with our 3D printing systems. The recommended file formats are STEP (.stp) and STL (.stl), as they provide the best accuracy and detail. If your design file is in a different format, we advise converting it to either STEP or STL to ensure optimal results. These formats preserve the geometric data and intricate details necessary for precise and high-quality prints. Should you need assistance with file conversion or have questions about specific formats, our support team is always ready to help.

The cost of our 3D printing service depends on several factors. These include the type of 3D printer chosen, the size and design complexity of the model, the material used, and the volume of parts required. Larger and more intricate designs typically require more resources and time, influencing the overall cost. Material choice also plays a significant role; different materials vary in price based on their properties and suitability for specific applications. At RapidDirect, we provide detailed quotes tailored to your project’s specifications. Understanding these variables helps you manage capital effectively while achieving high-quality results.

Choosing the right 3D printing technology depends on your project’s specific requirements. Consider factors such as the desired material, part complexity, surface finish, strength, and budget. For high-detail and smooth finishes, SLA is ideal. For strong, functional parts, SLS or HP MJF might be better suited. FDM is great for large, durable parts at a lower cost, while SLM is perfect for high-strength metal components. Consulting with our 3D printing experts can help you make an informed decision. Provide your design specifications, and we’ll recommend the best technology to meet your needs efficiently and cost-effectively.

3D Printing

Resources

3D Printing

Resources

3D Printing in Consumer Goods Manufacturing

ABS Acetone Smoothing: Methods, Materials, and Practical Tips

now, for free