Start A New CNC Quote

CNC Turning

With RapidDirect

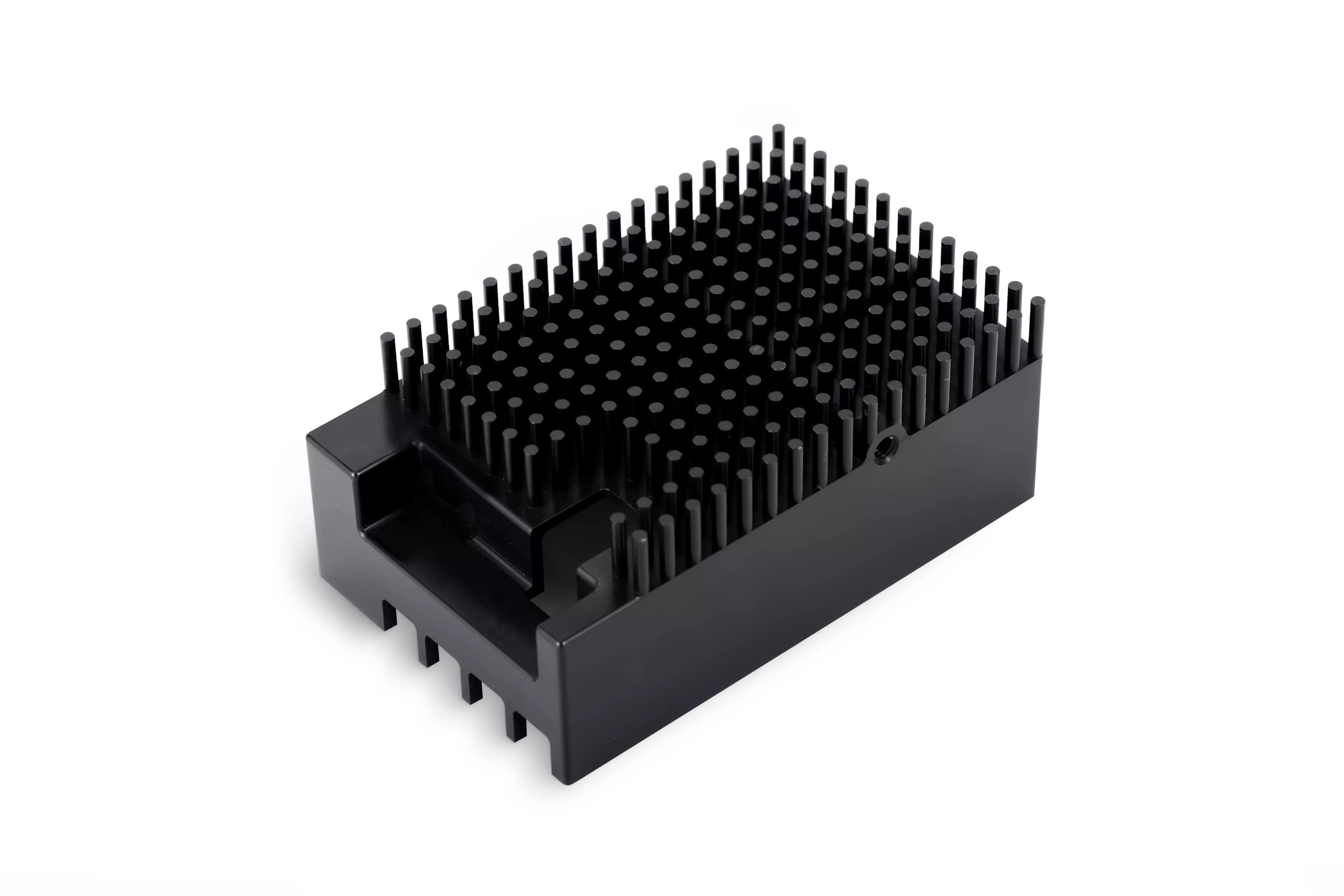

Take advantage of the on-demand CNC turning service and get reliable metal and plastic turned parts for your unique projects. With advanced technologies and expert technicians, RapidDirect produces high-quality custom prototypes and end-use production parts. Our CNC turning capabilities allow us to deliver turned parts with high accuracy, regardless of the complexity. You will get durable parts from flats to radial and axial holes, slots, and grooves as fast as one day.

Our precision CNC turning lathes provide low-cost parts for simple and complex cylindrical geometries. We also use Live tooling to create precise, complex geometries for features like axial and radial holes, grooves, slots, and flats. Full automation of these versatile machines allows us to produce hundreds of similar dimensions easier, faster, and cost-effectively.

RapidDirect

CNC Turning Solutions

Rapid Prototyping

Accelerate product development with our rapid machining services. We offer fast turnaround times and specialize in quick production of high-quality prototypes and mold tooling, aiding your design verification process.

Low and High-Volume Production

Whether you need small batches or large-scale production, we can offer you both. With stringent tolerance controls and comprehensive capabilities, we adapt to your volume requirements without compromising on quality.

CNC Turning Materials

Our CNC turning processes work with a diverse array of materials, including machine-grade metals and plastics. Whether you need precision turning of aluminum parts or other materials, we can produce accurate rapid prototypes and low-volume production runs to meet your needs. Check out some of the common materials for your CNC turning projects.

Aluminum is lightweight yet strong, with excellent machinability and corrosion resistance. Ideal for aerospace and automotive parts.

Alloys

Aluminum 6061, 6061-T6

Aluminum 2024

Aluminum 5052

Aluminum 5083

Aluminum 6063

Aluminum 6082

Aluminum 7075, 7075-T6

Aluminum ADC12 (A380)

LEARN MORECopper is known for its superior electrical conductivity and thermal properties, making it perfect for electrical components and heat exchangers.

Alloys

Copper C101(T2)

Copper C103(T1)

Copper C103(TU2)

Copper C110(TU0)

Beryllium Copper

Brass is durable and has a low friction coefficient, which makes it suitable for fittings, tools, and musical instruments that require precision.

Alloys

Brass C27400

Brass C28000

Brass C36000

Bronze is highly resistant to corrosion and metal fatigue, favored for bearings, bushings, and marine hardware.

Alloys

Tin Bronze

Steel is an alloy with high tensile strength and durability, commonly used in construction and automotive industries for its robustness.

Alloys

Steel 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36

Die steel

Alloy steel

Chisel tool steel

Spring steel

High speed steel

Cold rolled steel

Bearing steel

SPCC

Stainless steel is renowned for its corrosion resistance, making it a prime choice for medical devices and food processing equipment.

Alloys

Stainless Steel SUS201

Stainless Steel SUS303

Stainless Steel SUS 304

Stainless Steel SUS316

Stainless Steel SUS316L

Stainless Steel SUS420

Stainless Steel SUS430

Stainless Steel SUS431

Stainless Steel SUS440C

Stainless Steel SUS630/17-4PH

Stainless Steel AISI 304

Magnesium is the lightest structural metal, offering high strength-to-weight ratios, perfect for automotive and aerospace applications where weight is critical.

Alloys

Magnesium Alloy AZ31B

Magnesium Alloy AZ91D

Titanium boasts the highest strength-to-density ratio among metals, highly resistant to corrosion and fatigue, ideal for aerospace, medical, and marine applications.

Alloys

Titanium Alloy TA1

Titanium Alloy TA2

Titanium Alloy TC4/Ti-6Al 4V

ABS is strong, durable, and offers good resistance to heat and impact. It’s preferred for automotive components and consumer goods.

ABS Beige(Natural)

ABS Black

ABS Black Antistatic

ABS Milky White

ABS+PC Black

ABS+PC White

Polycarbonate is extremely durable and has high impact resistance, along with excellent clarity, used for bullet-proof glass and protective gear.

PC Black

PC Transparent

PC White

PC Yellowish White

PC+GF30 Black

PMMA, or acrylic, is known for its crystal clarity and weather resistance, making it ideal for outdoor fixtures and display cases.

PMMA Black

PMMA Transparent

PMMA White

POM is strong, with a low friction surface and good dimensional stability, perfect for precision parts in mechanical applications.

Dark brown (coffee) POM 100AF

POM Black

POM Blue

POM White

Nylon is versatile, strong, and wears well against friction, commonly used for gears, bearings, and other wear-resistant surfaces.

PA(Nylon) Blue

PA6 (Nylon)+GF15 Black

PA6 (Nylon)+GF30 Black

PA66 (Nylon) Beige(Natural)

PA66 (Nylon) Black

Polyethylene is lightweight and has high resistance to impact, widely used in packaging and containers.

PE Black

PE White

PEEK is renowned for its high temperature resistance and strength, often used in aerospace and medical implant manufacturing.

PEEK Beige(Natural)

PEEK Black

Polypropylene is tough, has excellent chemical resistance, and is used for automotive parts, containers, and in packaging.

PP Black

PP White

PP+GF30 Black

HDPE is known for its high strength-to-density ratio, resistance to impacts, and is used in making bottles and corrosion-resistant piping.

HDPE Black

HDPE White

HIPS is easy to machine and offers good dimensional stability and impact resistance, suitable for prototyping and modeling.

HIPS Board White

LDPE is soft, flexible, and used in applications where heat sealing is required, such as in tubing and plastic bags.

LDPE White

PBT is a strong, rigid plastic that is heat resistant and commonly used in electrical components and casings.

PBT Black

PBT Milky White(Natural)

PPA offers high heat resistance and stiffness, ideal for automotive and electrical applications that require durability at high temperatures.

PAI has exceptional thermal and chemical stability, used in high-performance parts in aerospace and automotive sectors.

PAI Brown

PET is strong, resistant to moisture and chemicals, and widely used in food containers and textile fibers.

PET Black

PET White

PET+GF30 Black

PET+GF30 White

PPS features outstanding chemical and heat resistance, suitable for automotive and aerospace components.

PPS Black

PPS White

PPS+GF30 Black

PPS+GF30 White

Polystyrene is lightweight and easy to machine, used for models, prototypes, and low-strength applications.

PS Transparent

PVC is robust, cheap, and has good chemical resistance, used in plumbing, medical devices, and cables.

PVC Grey

PTFE is known for its outstanding chemical resistance and low friction, making it perfect for non-stick coatings and gaskets.

Teflon (PTFE) Black

Teflon (PTFE) White

UPE has extremely long chains, resulting in a very tough material, ideal for high-abrasion applications like lining chutes.

UPE Black

UPE White

Bakelite is heat resistant and electrically non-conductive, perfect for electrical insulators and radio and telephone casings.

Bakelite Black

Bakelite Orange

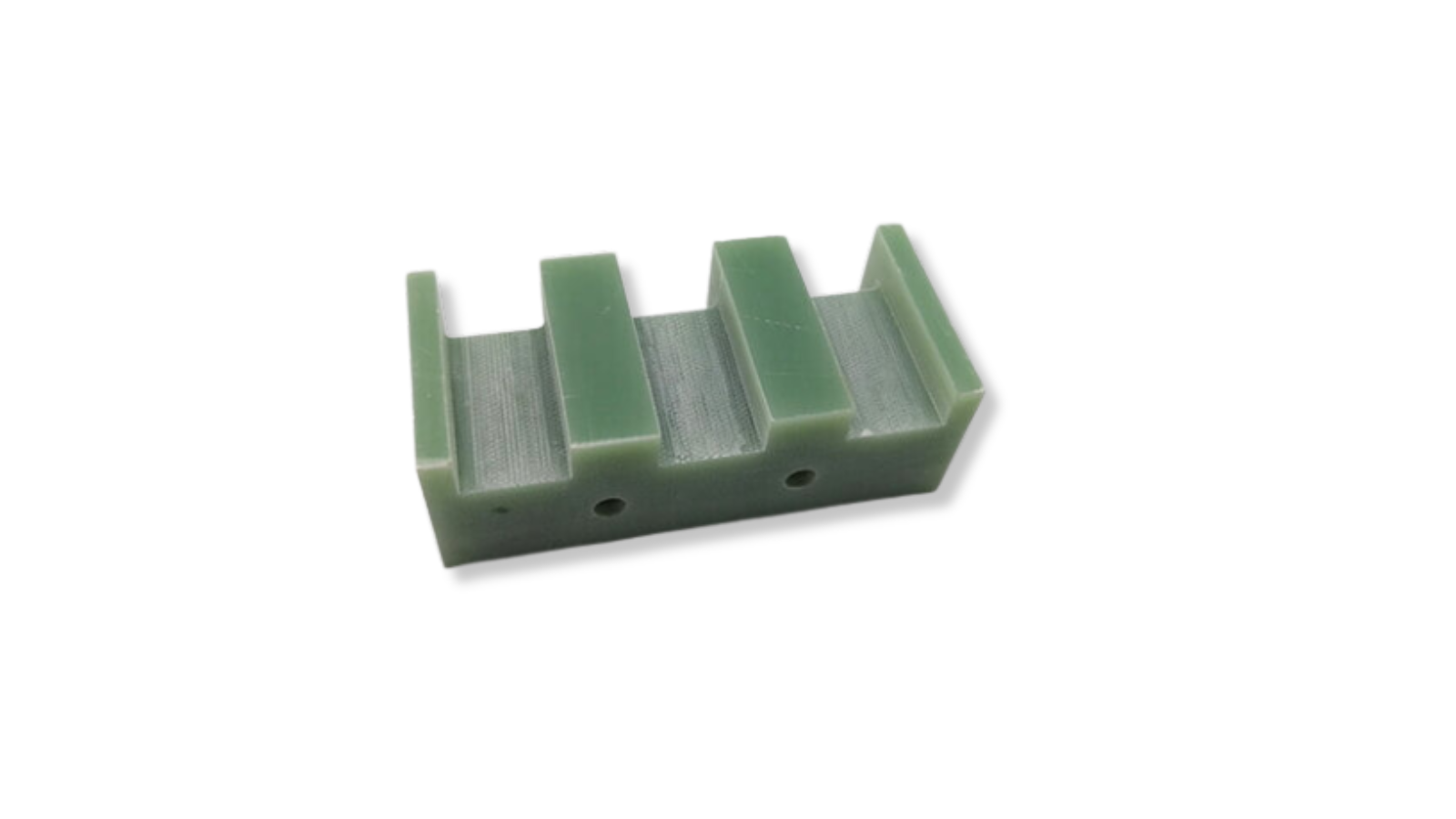

FR-4 is a flame-resistant material, primarily used in the electronics industry for circuit boards and insulators.

FR-4 Aqua Green

FR-4 Yellow

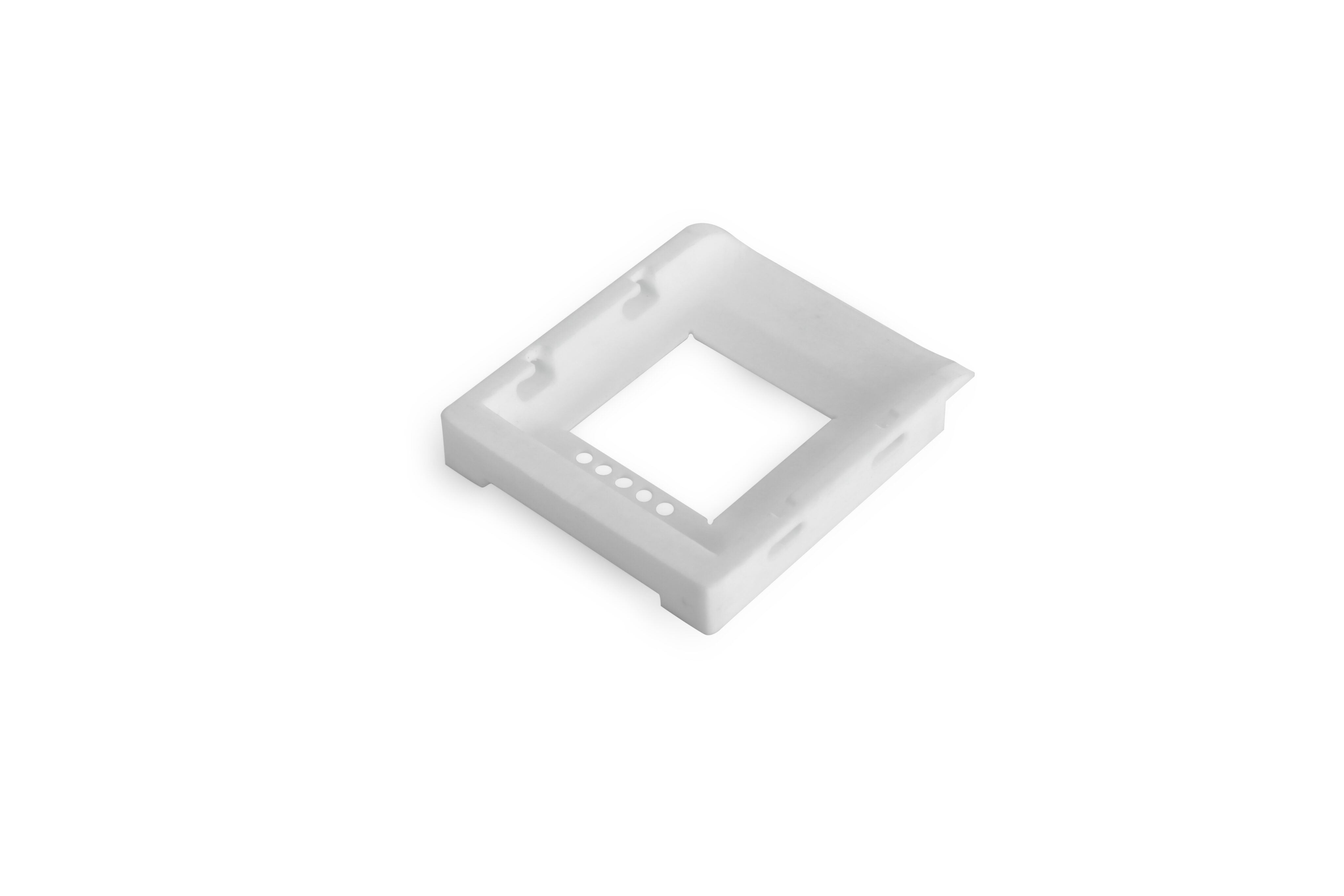

CNC Turning Surface Finishes

With a wide selection of surface finishes, RapiDirect can help improve the surface qualities of your products. Surface finishes applied to your CNC turned parts aim at improving their appearance, surface hardness and roughness, chemical and corrosion resistance, etc. They also help hide any visible tool marks from areas cut with live tooling. Here are some of your top choices.

Polishing

Tolerances for

CNC Turning

As an ISO 9001 certified company, we machine CNC turning lathe parts to meet tight tolerance requirements. Based on your design, our CNC lattes can reach tolerances of up to ±0.005”. Our standard tolerances for CNC milled metals is ISO 2768-m and ISO 2768-c for plastics.

| Description | |

|---|---|

| Maximum Part Size | Typically up to 500 mm in diameter and 1500 mm in length, though larger sizes can be accommodated with specific equipment. |

| Minimum Part Size | As small as 1 mm in diameter, depending on the material and machining setup. |

| General Tolerances | Standard tolerances of ±0.01 mm; tighter tolerances down to ±0.005 mm can be achieved based on the material and complexity of the part. |

| Lead Time | Standard lead times range from 3-7 days for small batches. Expedited services are available, reducing lead time to 24-48 hours depending on part complexity and material availability. |

CNC Turning

Design Guidelines

| Recommended Size | |

|---|---|

| Radii | Minimum internal radius of 0.5 mm recommended. Larger radii (up to 3 mm or more) can improve tool access and reduce stress concentrations in the part. |

| Threads and Tapped Holes | External and internal threads can be precisely cut. Standard thread sizes from M1.6 and larger are feasible. Ensure a minimum thread length of 1.5 times the diameter for stability. |

| Minumum Wall Thickness | Maintain a minimum wall thickness of 0.8 mm for metals and 1.5 mm for plastics to ensure structural integrity without compromising the machining process. |

| Text | Engraving should have a minimum character height of 2 mm and a depth of at least 0.5 mm to ensure legibility after machining. |

| Holes | Minimum hole diameter of 0.5 mm. For deep holes, maintain a diameter to depth ratio of 1:10 to avoid tool deflection and ensure hole quality. |

Start Your

CNC Machining Project

Kickstart your project with our easy-to-use online quoting platform. Upload a CAD file to receive instantly quotes, lead time, and DFM details for your CNC components. Specializing in CNC machining for metals and plastics, we provide adaptive production and shipping solutions to align with your product development needs.

Why

Choose Us

Parts

Experience unparalleled precision in each undertaking. Our advanced milling processes ensure components adhere to tight tolerances, as tight as ±0.01mm, resulting in seamless assembly and operational excellence.

Time

Accelerate your manufacturing cycle. RapidDirect domestic workshops and state-of-the-art machinery guarantee fast turnaround times, helping businesses maintain momentum and meet critical deadlines.

Support

No matter you whenever and whereever, navigate your CNC milling projects with confidence. Our seasoned specialists offer insightful guidance at every step, maximizing design optimization and output quality.

How Does CNC Turning Work?

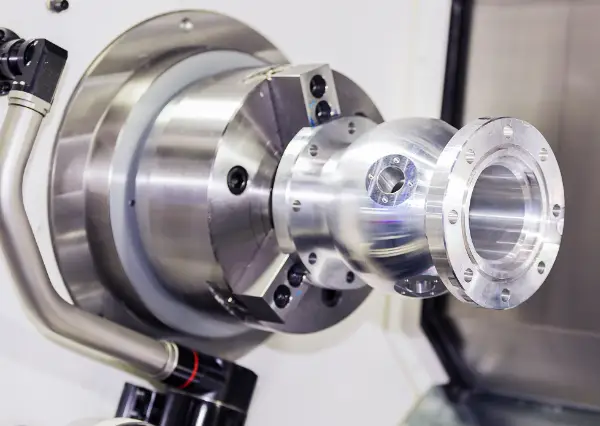

CNC turning is a subtractive manufacturing operation that uses computer-controlled lathes to precisely shape material into cylindrical parts. Initially, the design of the part is created using CAD software and converted into instructions for the CNC machine using CAM software. During setup, the correct cutting tools are installed, and a cylindrical workpiece is secured in the machine’s chuck, which holds and rotates the material.

As the machine operates, the workpiece spins at high speeds while the cutting tools move along various axes to carve, cut, and shape the material based on the program’s specifications. Operations such as facing, threading, knurling, and drilling are performed during this stage. A coolant is often applied to prevent overheating and to wash away debris.

After machining, the part may undergo additional finishing processes like sanding or polishing. The final step involves a thorough inspection to ensure the part meets all the required dimensions and tolerances. This process allows for high precision and repeatability, making CNC turning ideal for producing complex parts efficiently.

Advantages of CNC Turning

CNC turning offers several distinct advantages that make it a preferred method for manufacturing precise cylindrical parts. Here are some of the key benefits:

- Precision and Accuracy: Machines are capable of achieving extremely tight tolerances, essential for components that must fit seamlessly into complex assemblies.

- Efficiency: Once programmed and set up, these machines produce parts quickly and with consistent quality, often requiring minimal supervision, which accelerates production cycles.

- Flexibility: The ability to reprogram the machines for different designs quickly makes them highly adaptable to varying production needs, enhancing operational responsiveness.

- Repeatable: The automated nature ensures that each part is identical, even across large production volumes, crucial for maintaining quality in mass production.

- Reduced Labor Costs: Automation reduces the need for manual intervention, cutting labor costs and minimizing human error, thereby enhancing overall efficiency and cost-effectiveness.

- Material Versatility: The machines handle a wide range of materials, from various metals to plastics and composites, accommodating diverse manufacturing demands.

- Improved Safety: The enclosed, automated operation minimizes human interaction, reducing the risk of accidents and promoting a safer workplace.

Applications of CNC Turning

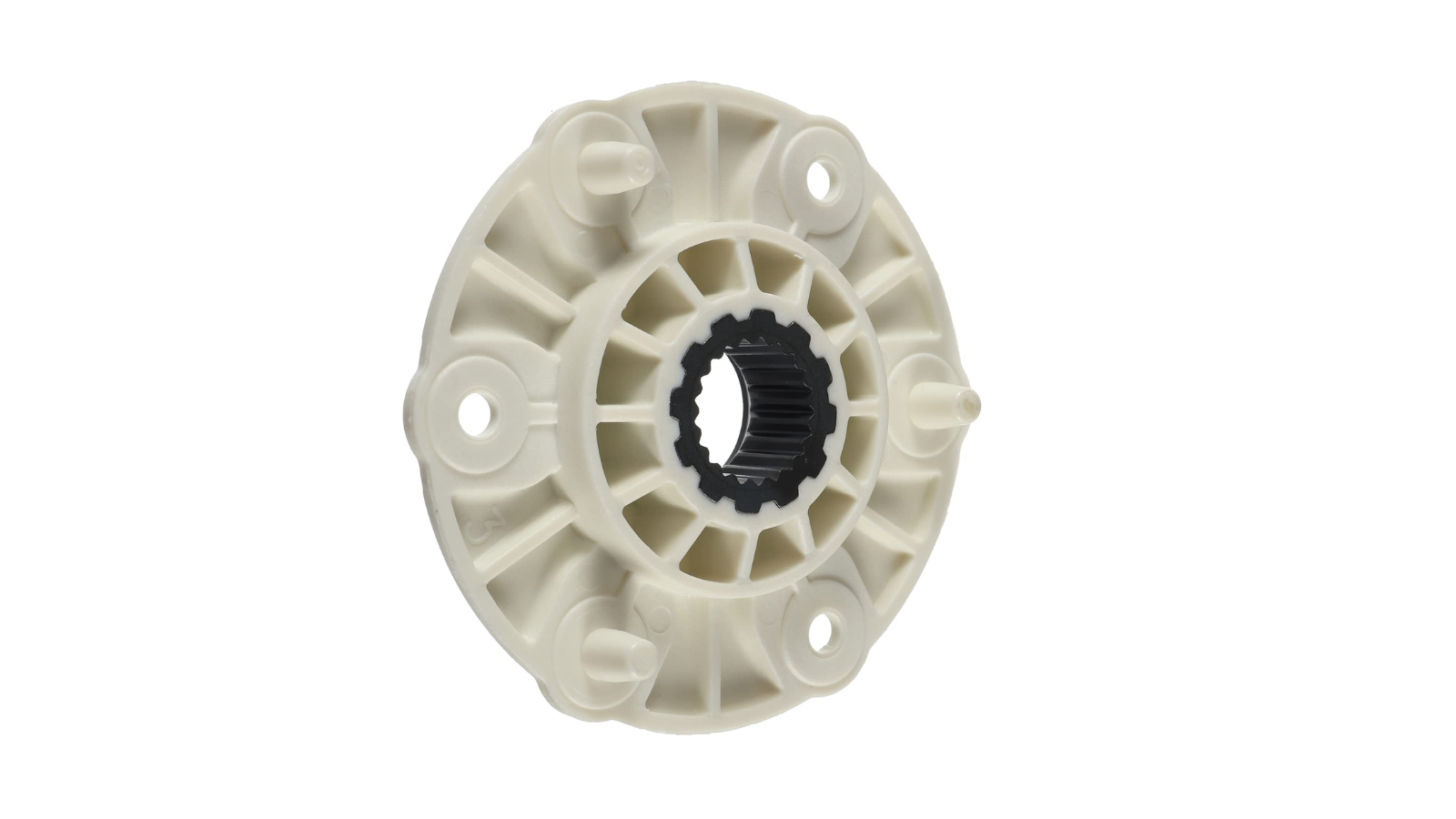

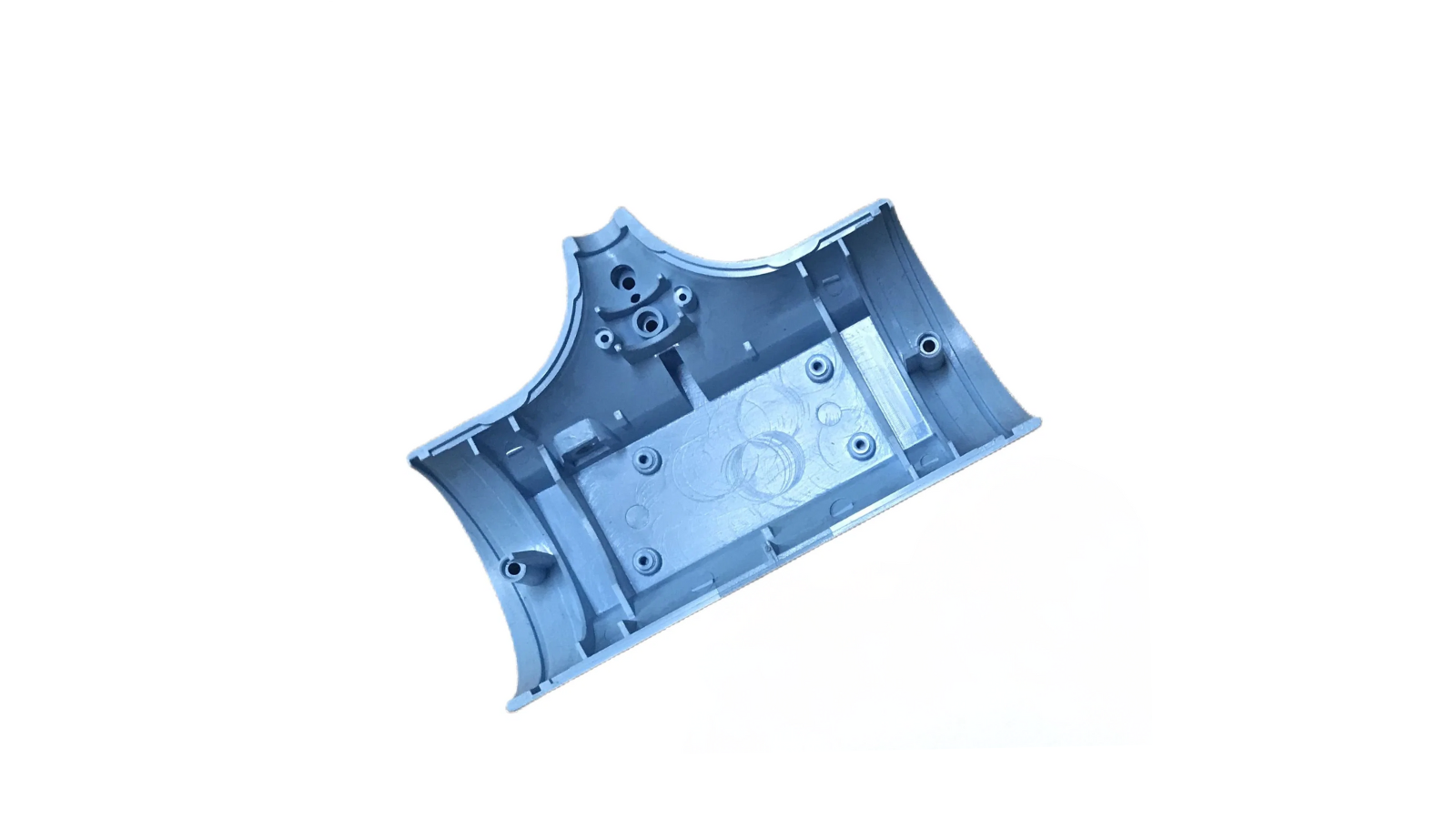

As a leading turned parts manufacturer, RapidDirect utilizes CNC turning to produce a variety of precision components, often used in mechanisms where accuracy and fit are critical. Here’s an overview of some typical parts made through this process:

- Shafts are fundamental in various machines, serving as axes or pivots. Precision in diameter and surface finish is crucial for their interaction with other mechanical parts.

- Flanges connect pipes, pumps, or valves, requiring accurate machining to ensure a secure fit and avoid leaks.

- Bushings and Sleeves provide smooth surfaces for other parts to move against or through, necessitating exact internal diameters and smooth finishes.

- Pins are small but vital for aligning or holding components together, often needing precise dimensions to fit snugly into place.

- Knobs and Dials are user interface elements for machinery and electronic devices, where aesthetics and precise dimensions enhance usability.

- Wheels and Rollers are integral to systems like conveyors, where consistent shape and smoothness reduce friction and wear.

FAQs

CNC turning produces cylindrical and symmetrical parts around their axis. This process is typically used for manufacturing items like shafts, pins, rods, bushings, and pulleys. It’s also well-suited for creating external threads, internal boreholes, and even complex contours on cylindrical surfaces. The precision of CNC turning allows for tight tolerances and a smooth finish, making it ideal for parts that require exact fits and movements, commonly found in automotive, aerospace, and manufacturing machinery.

Yes, CNC turning is versatile enough to handle various materials, including plastics. Plastics commonly turned on CNC lathes include ABS, Polycarbonate, PTFE (Teflon), Nylon, and Acetal. Each material offers different properties; for instance, Nylon is known for its strength and friction resistance, while Acetal provides excellent machinability and dimensional stability. Turning plastics requires precise control of cutting speeds and tool selection to prevent melting or deformation, ensuring the production of high-quality, precise parts suitable for a range of applications.

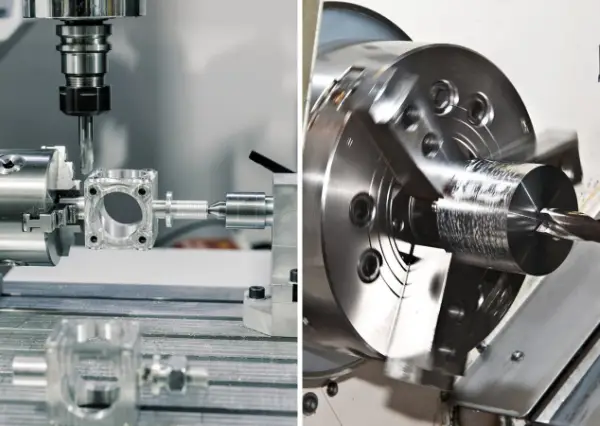

CNC milling and CNC turning are both subtractive manufacturing processes, but they differ in how the material is removed.

In CNC milling, the workpiece is stationary, and the cutting tool moves across multiple axes to remove material and create the desired shape. This process is ideal for complex parts with various features such as slots, holes, and contours.

On the other hand, CNC turning involves rotating the workpiece while a stationary cutting tool removes material. This method is best suited for producing cylindrical parts, such as shafts, rings, and bolts. While milling can handle more complex geometries, turning is typically faster and more efficient for producing round parts.

A CNC turning center is a computer-controlled machine designed to manufacture cylindrical parts with precision. It is capable of producing a wide range of components, including shafts, pins, screws, bushings, and other intricate parts. Highly versatile, the CNC turning center can perform various operations such as facing, turning, threading, grooving, drilling, and even complex contouring. Its advanced automation allows for consistent production quality and efficient handling of both simple and complex CNC turning parts across different industries.

CNC Turning

Resources

now, for free