At RapidDirect, we recognize that producing high-quality parts is essential to your success. Our CNC machining experts are committed to delivering precision, efficiency, and consistent quality at every step of the production process.

Custom Online CNC

Machining Services

- Tolerance down to 0.001 inches.

- Choose from 100+ materials, 60+ surface finishes.

- ISO 9001:2015, ISO 13485, ISO14001:2015, IATF 16949:2016 certified.

- Lead times as short as 1 day.

Uploading

Max. file size: ≤15MB

Custom Online CNC Machining Services

Start A New CNC Quote

Max. file size: ≤15MB

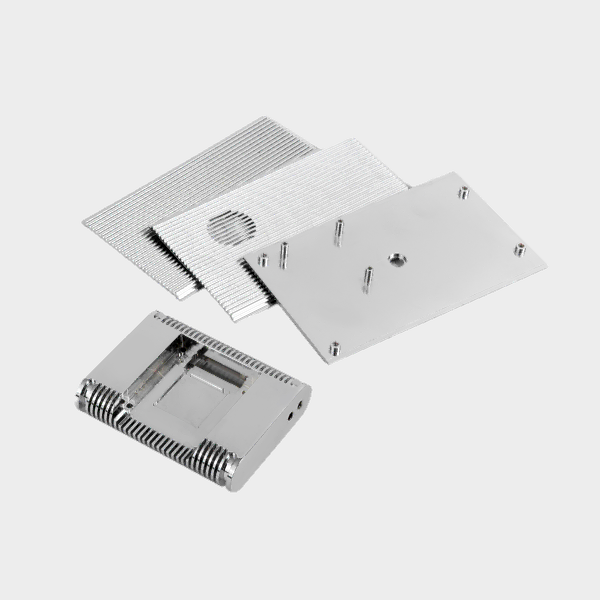

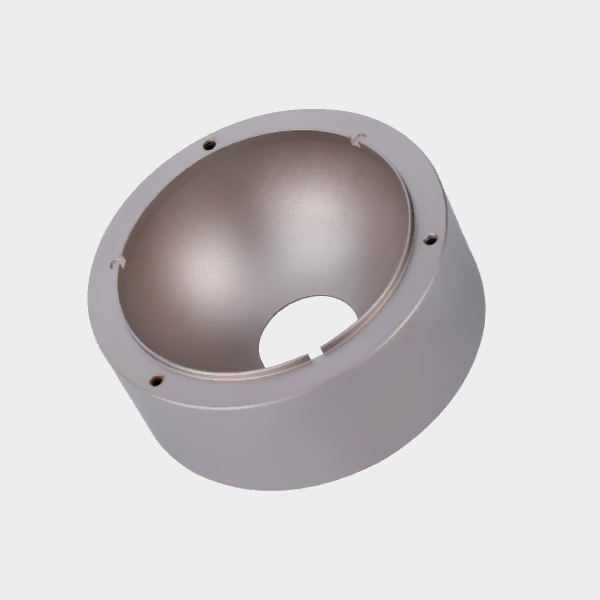

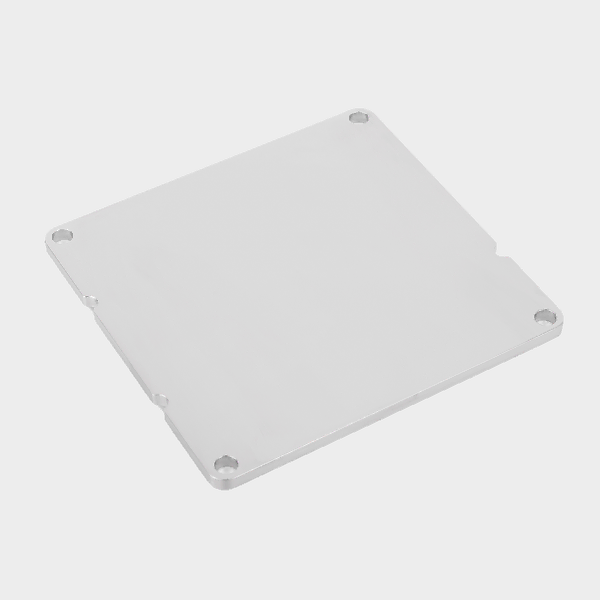

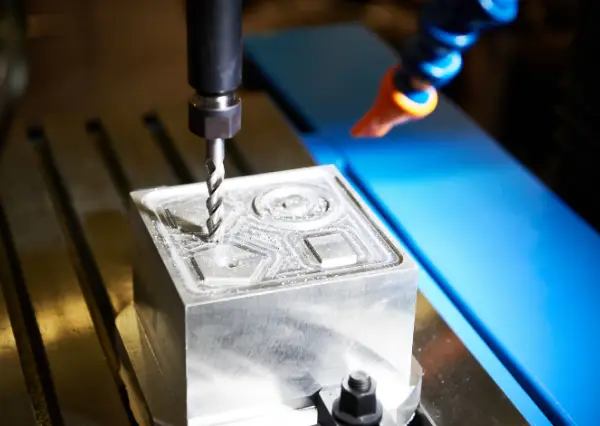

CNC Machining Services for Custom Parts

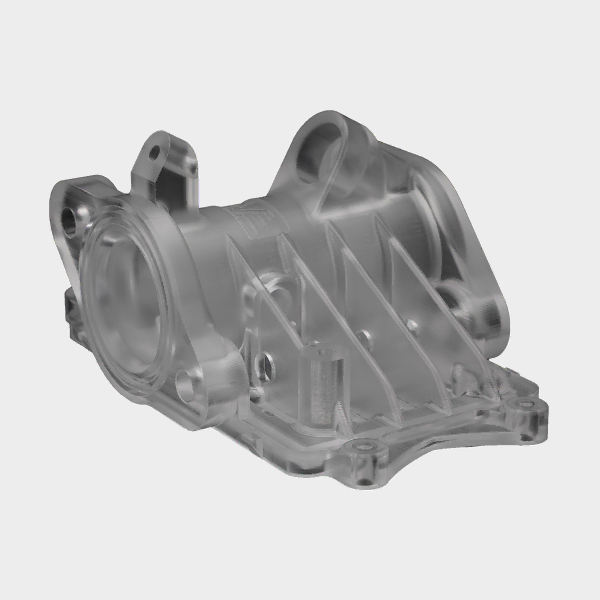

Custom CNC Milling Services

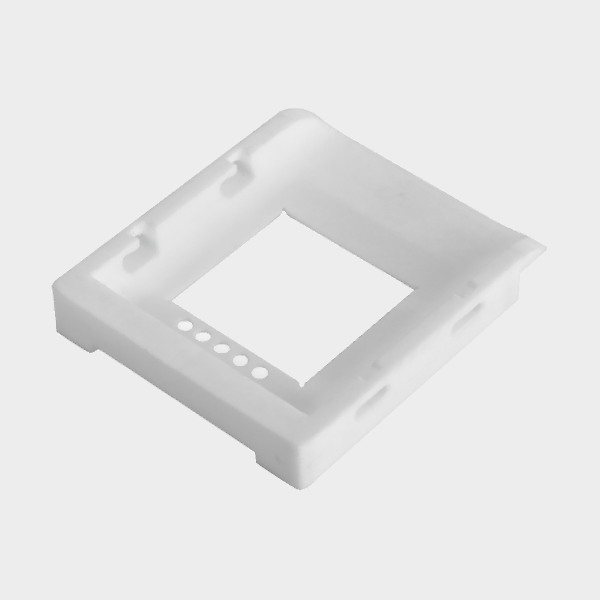

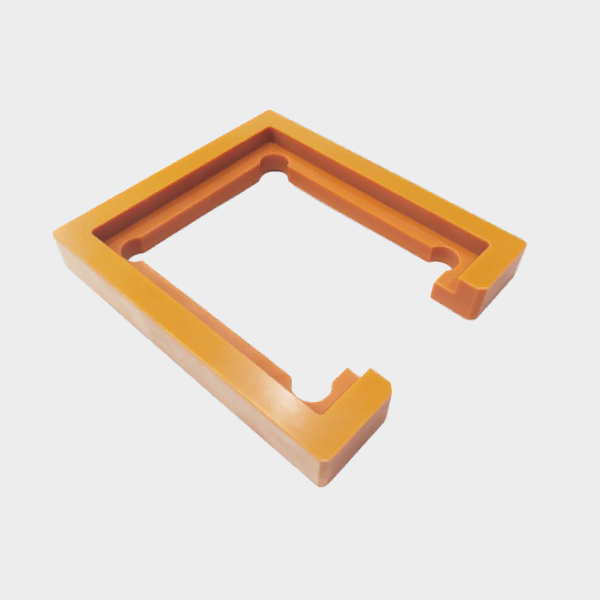

With 200+ milling centers, including 3-axis, 4-axis and advanced 5-axis CNC mills, we can easily handle tigh-tolerance parts and complex geometries in plastic and metal. Serving diverse industries and specializing in mold making.

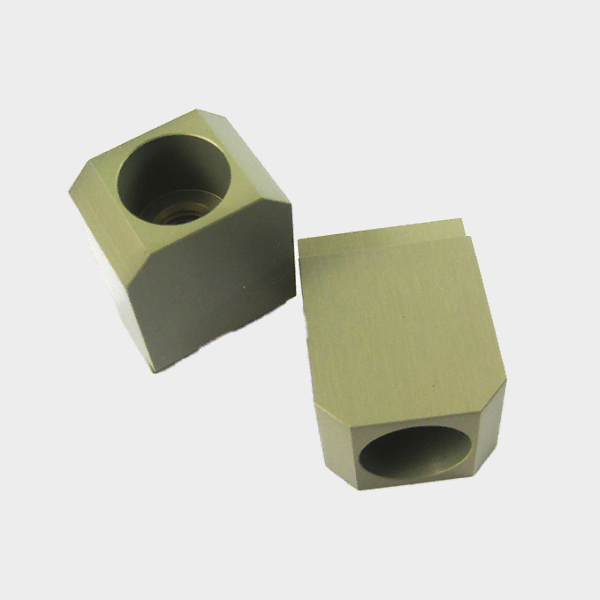

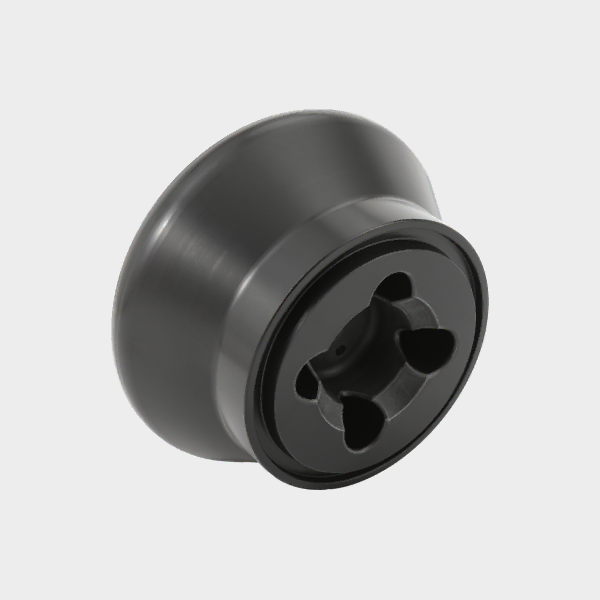

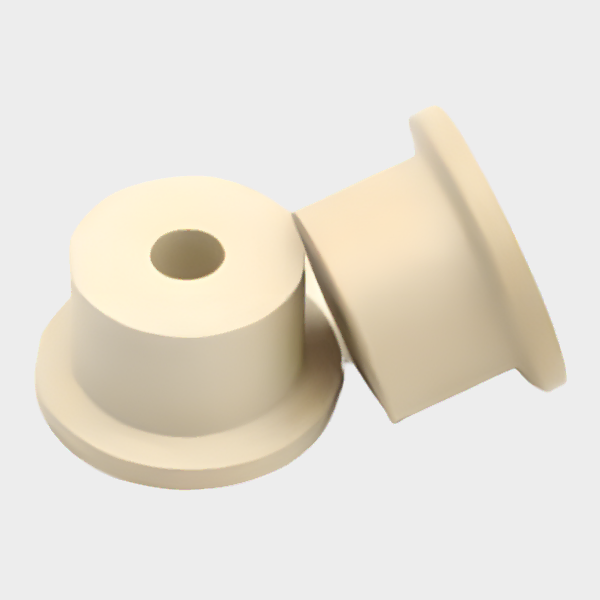

Custom CNC Turning Services

With our CNC lathes, turning centers, and mill-turn machines, we can create cylindrical-shaped workpieces, also for square or hexagonal-shaped raw materials. Turned prototypes and production parts delivered in just a few days.

A Robust Network of

CNC Machine Shops

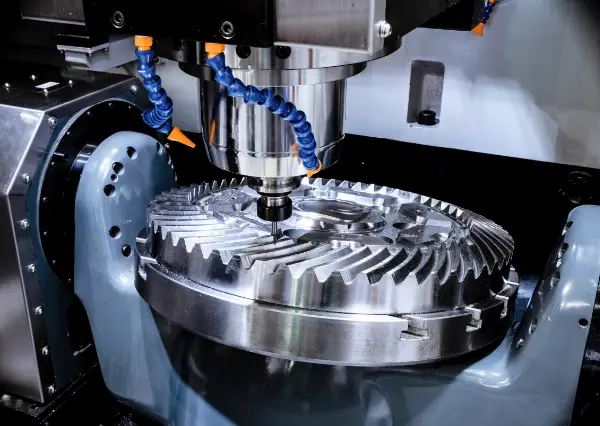

At RapidDirect, we operate a dedicated CNC machine shop alongside an extensive network of partner facilities across China. Our capabilities go beyond standard CNC machines, including grinders for smooth finishes, wire cutters for precision cuts, and EDM machines for intricate shapes. This diversity enables us to handle complex designs and create CNC-machined parts that meet specific requirements. Our expert machinists consistently achieve ultra-precise tolerances as tight as 0.01mm, ensuring perfect integration into larger assemblies.

We also leverage automated production lines, where machines seamlessly collaborate to deliver high-volume production efficiently while minimizing errors and keeping projects on track.

700+

Machines Set

120+

Countries Shipped

20,000+

Customers Served

CNC Machining Materials

From aluminum and steel to brass and plastics, we’ve got a wide selection of CNC materials for your custom parts.

Aluminium

Aluminum is lightweight, strong, and easy to machine, positioning it great for various applications like aerospace and automotive parts. Its corrosion resistance also adds to its appeal in outdoor projects and structural components.

| Color: | Silver |

| Subtypes: | Aluminum 6061, 6061-T6, Aluminum 2024, Aluminum 5052, Aluminum 5083, Aluminum 6063, Aluminum 6082, Aluminum 7075, 7075-T6, Aluminum ADC12 (A380) |

| Available Finish: | As machined, Anodizing, Powder coating, Electroplating, Painting, Sand blasting, Polishing |

| Price: | $$ |

| Lead Time: | ABout 5 business days |

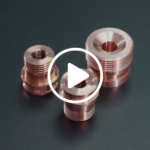

Copper

Copper is highly conductive and malleable, making it a top choice for electrical wiring and plumbing. Its natural antibacterial properties also make it ideal for medical applications, while its aesthetic appeal suits decorative items and artwork.

| Color: | Red-orange |

| Subtypes: | Copper C101(T2), Copper C103(T1), Copper C103(TU2), Copper C110(TU0), Beryllium Copper |

| Available Finish: | As machined, Polishing, Sand blasting, Tumbling, Electropolish, Alodine, Heat treatment, Black oxidize, Electroless nickel, Chrome plating, Brushed finish |

| Price: | $$$ |

| Lead Time: | About 5 business days |

Bronze

Bronze, an alloy of copper and tin, is known for its durability and resistance to corrosion. It’s widely used in marine applications, sculptures, and bearings, thanks to its strength and ability to withstand harsh environments.

| Color: | Metallic brown |

| Subtypes: | Tin Bronze |

| Available Finish: | As machined, Polishing, Sand blasting, Tumbling, Electropolish, Alodine, Heat treatment, Black oxidize, Electroless nickle, Chrome plating, Powder coating, Brushed finish |

| Price: | $$$ |

| Lead Time: | About 5 business days |

Steel

Steel is a strong and versatile material, widely used in construction and manufacturing. Its high tensile strength makes it suitable for structural components, while various Subtypes enhance its properties for specialized applications, like tools and machinery.

| Color: | Silver Grey |

| Subtypes: | Steel 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36, Die steel, Alloy steel, Chisel tool steel, Spring steel, High speed steel, Cold rolled steel, Bearing steel, SPCC |

| Available Finish: | As machined, Electroplating, Passivation, Powder coating |

| Price: | $$$ |

| Lead Time: | About 7 business days |

Stainless Steel

Stainless steel is resistant to rust and staining, making it perfect for kitchen appliances and medical equipment. Its strength and aesthetic appeal also make it a popular choice for architectural designs and automotive parts.

| Color: | Silver Grey |

| Subtypes: | Stainless Steel SUS201, SUS303, SUS 304, SUS316, SUS316L, SUS42, SUS430, SUS431, SUS440C, SUS630/17-4PH, AISI 304 |

| Avaiblae Finish: | As machined, Electroplating, Passivation, Powder coating |

| Price: | $$$ |

| Lead Time: | About 7 business days |

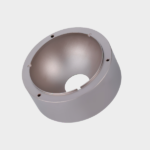

Magnesium

Magnesium is lightweight yet strong, often used in aerospace and automotive applications where reducing weight is critical. Its machinability allows for complex shapes, and it's also utilized in various electronic devices for its excellent conductivity.

| Color: | White-silver |

| Subtypes: | Magnesium Alloy AZ31B, AZ91D |

| Available Finish: | As machined, Polishing, Sand Blasting, Tumbling, Alodine, Heat treatment, Anodizing, Teflon coating, Electroless nickel, Painting, Powder coating, Electrophoresis |

| Price: | $$$$$ |

| Lead Time: | About 8 business days |

Titanium

Titanium is incredibly strong and lightweight, making it ideal for aerospace and medical implants. Its resistance to corrosion and biocompatibility enhance its use in demanding environments, while its high strength-to-weight ratio suits various industrial applications.

| Color: | Silver |

| Subtypes: | Titanium Alloy TA1, Alloy TA2, Alloy TC4/Ti-6Al 4V |

| Available Finish: | As machined, Polishing, Sand Blasting, Tumbling, Electropolish, Alodine, Anodizing, Electroless nickel, Painting, Powder coating, Brushed finish |

| Price: | $$$$$ |

| Lead Time: | About 8 business days |

ABS

ABS is tough, heat-resistant, and impact-resistant. Lightweight and easy to work with, this material suits car parts and consumer goods where durability matters but cost is also important.

| Color: | Lighe Beige Black |

| Subtypes: | ABS Beige(Natural), ABS Blac, ABS Black Antistati, ABS Milky Whit, ABS+PC Black, ABS+PC White |

| Available Finish: | As machined, Sand blasting, Tumbling, Teflon coating, Painting, Powder coating, Electrophoresis |

| Price: | $$ |

| Lead Time: | About 6 business days |

PC

Polycarbonate is super durable and clear, with amazing impact resistance. Commonly found in bulletproof glass and safety gear, it can take a hit without cracking.

| Color: | Black White |

| Subtypes: | PC Black, PC Transparent, PC White, PC Yellowish White, PC+GF30 Black |

| Available Finish: | As machined, Sand blasting, Tumbling, Painting, Brushed Finish |

| Price: | $$ |

| Lead Time: | About 6 business days |

PMMA (Acrylic)

PMMA (acrylic) is clear, weather-resistant, and won't fade. Ideal for outdoor displays, signage, and lighting, it holds up well in the elements.

| Color: | Black White |

| Subtypes: | PMMA Black, PMMA Transparent, PMMA White |

| Available Finish: | As machined, Sand blasting, Tumbling, Painting |

| Price: | $ |

| Lead Time: | About 6 business days |

POM

POM is strong and has a low-friction surface, making it perfect for precision parts like gears and bearings where things need to fit just right and work smoothly.

| Color: | Black White Blue |

| Subtypes: | Dark brown (coffee) POM 100AF, POM Black, POM Blue, POM White |

| Available Finish: | As machined, Sand blasting, Tumbling, Painting |

| Price: | $$ |

| Lead Time: | About 6 business days |

PA (Nylon)

Nylon is versatile, tough, and resists wear. Often chosen for gears, bearings, and other parts that handle constant friction and heat without breaking down.

| Color: | Black Blue |

| Subtypes: | PA(Nylon) Blue, PA6 (Nylon)+GF15 Black, PA6 (Nylon)+GF30 Black, PA66 (Nylon) Beige(Natural), PA66 (Nylon) Black |

| Available Finish: | As machined, Sand blasting, Tumbling, Teflon coating, Painting, Powder coating |

| Price: | $$ |

| Lead Time: | About 6 business days |

PE

Polyethylene is lightweight and tough, with great impact resistance. It's a go-to material for packaging, containers, and anything that needs to resist cracking under pressure.

| Color: | Black White |

| Subtypes: | HDPE, UHMW-PE, LDPE |

| Available Finish: | As machined, Sand blasting, Tumbling, Painting, Powder coating |

| Price: | $$ |

| Lead Time: | About 6 business days |

PEEK

PEEK is strong and can handle high temperatures without losing its strength. Found in high-performance industries like aerospace and medical implants, it's built for extreme conditions.

| Color: | Beige Black |

| Subtypes: | PEEK Beige(Natural), PEEK Black |

| Available Finish: | As machined, Sand blasting, Tumbling, Painting, Powder coating |

| Price: | $$$$$ |

| Lead Time: | About 8 business days |

PP

Polypropylene is tough, chemical-resistant, and handles higher temps. It's commonly found in car parts, containers, and packaging, especially where exposure to heat or chemicals is common.

| Color: | Black White |

| Subtypes: | PP Black, PP White, PP+GF30 Black |

| Available Finish: | As machined, Sand blasting, Tumbling, Painting, Powder coating |

| Price: | $ |

| Lead Time: | About 6 business days |

HDPE

HDPE is super strong and impact-resistant, with a high strength-to-density ratio. Ideal for bottles, containers, and pipes that need to withstand outdoor wear and tear.

| Color: | Black White |

| Subtypes: | HDPE Black, HDPE White |

| Available Finish: | As machined, Sand blasting, Tumbling, Painting, Powder coating, Teflon coating |

| Price: | $$ |

| Lead Time: | About 6 business days |

HIPS

HIPS is easy to machine and holds up well to impact. This makes it an excellent choice for prototypes, models, and temporary displays where you need something light but sturdy.

| Color: | White |

| Subtypes: | HIPS Board White |

| Available Finish: | As machined, Sand blasting, Tumbling, Painting, Powder coating, Brushed finish |

| Price: | $$ |

| Lead Time: | About 6 business days |

LDPE

LDPE is soft, flexible, and resistant to cracking. Perfect for plastic bags, tubing, and shrink wrap where heat sealing is essential.

| Color: | White |

| Subtypes: | LDPE White |

| Available Finish: | As machined, Painting, Powder coating, Teflon coating |

| Price: | $$ |

| Lead Time: | About 6 business days |

PBT

PBT is rigid, heat-resistant, and resists moisture. This material is often found in electrical parts, automotive components, and industrial connectors where high heat or wet conditions are a concern.

| Color: | Black Milkey White |

| Subtypes: | PBT Black, PBT Milky White (Natural) |

| Available Finish: | As machined, Sand blasting, Tumbling, Painting, Powder coating |

| Price: | $$ |

| Lead Time: | About 6 business days |

PPA

PPA offers heat resistance and stiffness. It's ideal for automotive and electrical applications where durability at high temperatures is essential.

| Color: | Beige |

| Subtypes: | PPA Beige |

| Available Finish: | As machined, Sand blasting, Tumbling, Painting, Teflon coating, Brushed finish |

| Price: | $$ |

| Lead Time: | About 6 business days |

PAI

PAI is known for its amazing thermal and chemical stability. A top choice for aerospace and automotive sectors, it's used in high-performance parts that withstand extreme conditions.

| Color: | Black Brown |

| Subtypes: | PAI 4203, 4503, 4301, 4501 |

| Available Finish: | As machined, Sand blasting, Tumbling, Heat Treatment, Teflon Coating, Painting |

| Price: | $$ |

| Lead Time: | About 8 business days |

PET

PET is strong, moisture-resistant, and recyclable. Commonly found in food containers, bottles, and textiles, it resists wear and tear over time.

| Color: | Black White |

| Subtypes: | PET Black, PET White, PET+GF30 Black, PET+GF30 White |

| Available Finish: | As machined, Sand blasting, Tumbling, Teflon Coating, Painting |

| Price: | $$ |

| Lead Time: | About 6 business days |

PPS

PPS is heat- and chemical-resistant, making it a great fit for automotive, aerospace, and industrial parts exposed to harsh environments that need to stay solid under stress.

| Color: | Black White |

| Subtypes: | PPS Black, PPS White, PPS+GF30 Black |

| Available Finish: | As machined, Sand blasting, Tumbling, Teflon Coating, Painting |

| Price: | $$ |

| Lead Time: | About 6 business days |

PS

Polystyrene is lightweight and easy to shape, making it a popular option for models, prototypes, and disposable packaging where strength isn't the top concern but shaping is.

| Color: | Transparent |

| Subtypes: | PS Transparent |

| Available Finish: | As machined, Sand blasting, Painting |

| Price: | $$ |

| Lead Time: | About 6 business days |

PVC

PVC is durable, affordable, and resistant to chemicals. Found in plumbing pipes, medical devices, and electrical cables, it resists corrosion and wear.

| Color: | Grey |

| Subtypes: | PVC Grey |

| Available Finish: | As machined, Sand blasting, Painting, Teflon coating, Powder coating |

| Price: | $$ |

| Lead Time: | About 6 business days |

PTFE (Teflon)

PTFE is chemically resistant, low friction, and stable at high temperatures. Commonly used in non-stick coatings, gaskets, and seals where performance in tough conditions is a must.

| Color: | Black White |

| Subtypes: | Teflon (PTFE) Black, Teflon (PTFE) White |

| Available Finish: | As machined, Sand blasting, Powder coating, Brushed finish |

| Price: | $$ |

| Lead Time: | About 6 business days |

UPE

UPE is tough with long polymer chains, making it ideal for abrasion-resistant applications like lining chutes and wear-resistant surfaces that see a lot of action.

| Color: | Black White |

| Subtypes: | UPE Black, UPE White |

| Available Finish: | As machined, Sand blasting, Teflon coating, Painting |

| Price: | $$ |

| Lead Time: | About 6 business days |

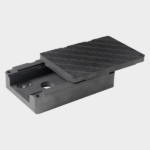

Bakelite

Bakelite is heat-resistant, electrically non-conductive, and super durable. It’s found in electrical insulators and vintage electronics, where safety and long-lasting performance are critical.

| Color: | Black Orange |

| Subtypes: | Bakelite Black, Bakelite Orange |

| Available Finish: | As machined, Painting, Powder coating, Brushed finish |

| Price: | $$ |

| Lead Time: | About 6 business days |

CNC Machining Surface Finishes

Looking for the right finish? Choose from 20+ options to meet both your functional and aesthetic needs.

Polishing

Tolerances for CNC Machining

Our CNC machines operate with precision tolerances that meet industry standards, ensuring that every part is consistently accurate and fits perfectly with other components.

| Description | |

|---|---|

| General Tolerances | Metals : ISO 2768-m Plastics : ISO 2768-c |

| Precision Tolerances | RapidDirect can manufacture and inspect parts with strict tolerances according to your drawing specifications and GD&T annotations, including tolerances tighter than +/- 0.001 inches. |

| Min Wall Thickness | 0.5mm |

| Min End Mill Size | 0.5mm |

| Min Drill Size | 1mm |

| Maximum Part Size | CNC Milling: 4000×1500×600 mm CNC Turning: 200×500 mm |

| Minimum Part Size | CNC Milling: 5×5 ×5 mm CNC Turning: 2×2 mm |

| Production Volume | Prototoyping: 1-100 pcs Low volume: 101-10,000 pcs High volume: Above 10,001 pcs |

| Lead Time | 5 bussiness days for most projects. Delivery of simple parts can be as fast as 1 day. |

Design Guidelines for CNC Machining

Optimize your designs for manufacturability with our helpful guidelines. Our experts provide feedback on your custom machined part for the best results in CNC machining.

| Description | |

|---|---|

| Radii | In CNC machining, sharp internal corners on a workpiece will naturally form rounded corners (radii). The depth must not exceed 12 times the diameter of the drill. For end mills, the depth must not exceed 10 times the diameter of the tool. |

| Threads and Tapped Holes | Diameter Φ 1.5-5 mm, depth: 3 times the diameter. Diameter Φ 5 mm or larger, depth: 4-6 times the diameter. RapidDirect can produce threads of any specification and size as required by the customer. |

| Undercuts | Square profiles, full radius, dovetail profiles. |

| Text | CNC Milling: Minimum width of 0.5 mm and depth of 0.1 mm. CNC Turning: RapidDirect can use laser marking to create standard text for CNC turned parts. RapidDirect can create standard text via CNC engraving or laser engraving as per customer requirements. |

CNC Machining Design Guide

This guide outlines key design considerations and guidelines to ensure the best results for CNC machined parts.

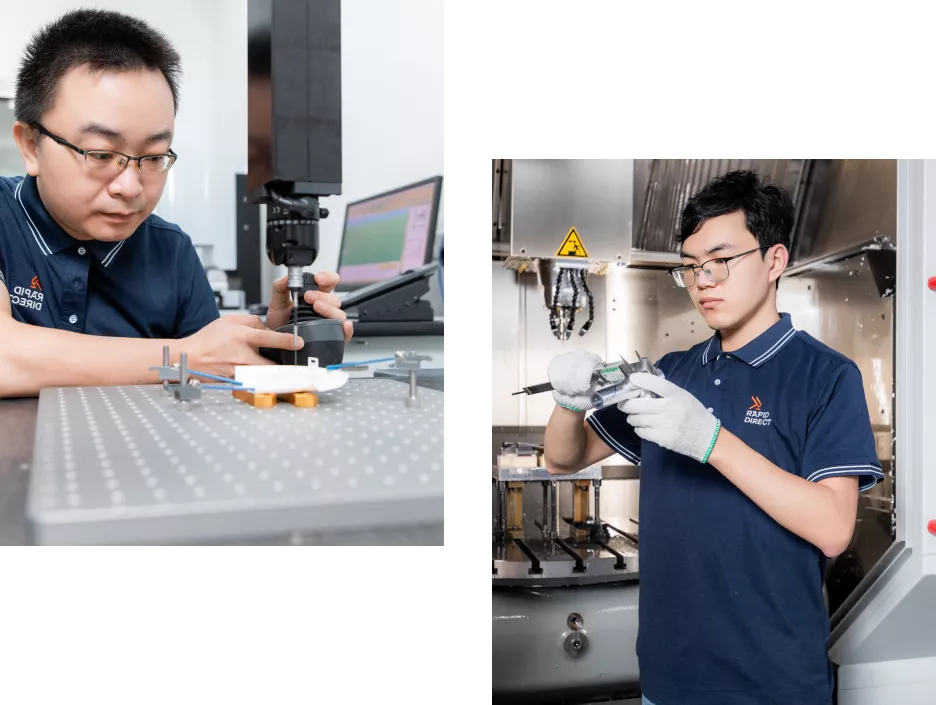

High-Quality CNC Machining, Every Time

We uphold a comprehensive quality control and assurance system throughout each phase of CNC machining, whether your project requires simple or complex components in small or large quantities. Every part implement strict inspection using advanced equipment such as CMM, two-dimensional measuring tools, XRF analyzers, gauges, micrometers, and calipers.

- 20+ inspection equipment

- 30+ quality engineers

- ISO 9001:2015, ISO 13485, ISO 14001, and IATF 16949

RapidDirect CNC Machining Solutions

Rapid Prototyping

Accelerate product development with our rapid machining services. We offer fast turnaround times and specialize in quick production of high-quality prototypes and mold tooling, aiding your design verification process.

Low and High-Volume Production

Whether you need small batches or large-scale production, we can offer you both. With stringent tolerance controls and comprehensive capabilities, we adapt to your volume requirements without compromising on quality.

A Robust Network of CNC Machine Shops

CNC machining begins with a computer design of a part. Machines then precisely remove material to turn the design into a real machined part. This cutting can be done from different angles using machines that have 3, 4, or 5 moving parts, known as axes.

At RapidDirect, we have our own main CNC machine shop and a broad network of partner shops throughout China. Our facilities aren’t limited to just basic CNC machines. We also have grinders for smoothing surfaces, wire cutters for precise cuts, and EDM machines for detailed shapes. This variety allows us to tackle complex designs that produce unique CNC machined parts with specific requirements. Our skilled machinists work with exceptional accuracy, achieving tolerances as precise as 0.01mm. This level of detail is crucial for components that must fit perfectly into larger assemblies.

We also use automated production lines. These are setups where machines work together smoothly and quickly, which helps us produce large quantities faster and reduces the chance of errors. This efficiency means we can deliver quality machined parts quickly to meet our clients’ needs, keeping projects on schedule.

700+

Sets of Machine

120+

Countries Shipped

20,000+

Customers Served

RapidDirect CNC Machining Solutions

Whether you’re creating a small batch of custom parts or scaling up for high-volume production, RapidDirect custom CNC machining services offer the flexibility you need.

Rapid Prototyping

- Lead Time: 1-5 business days

- Capability: 1-100 pcs

- Get 20% off the price

Low Volume Manufacturing

- Lead Time: 5-15 business days

- Capability: 101-10,000 pcs

- Meet tight specifications

End-use Production

CNC production machining is the best solution for producing a thousand parts or more efficiently. Leveraging a diverse selection of materials and automation and multi-axis capabilities, RapidDirect delivers high-volume production with tight tolerances, superior dimensional accuracy, high reliability and fast turnaround times.

- Lead Time: 2-4 weeks

- Capability: Above 10,001 pcs

- Consistent Quality

Start Your CNC Machining Project

Upload your CAD file to get instant quotes, lead times, and DFM feedback. Various materials, flexible production, and shipping options available. Get started.

CNC Machining for Various Industries

From automotive to aerospace, RapidDirect’s CNC machining meets the precise needs of diverse industries. We work with independent inventors, designers, and large-scale companies, serving over 20,000 customers worldwide.

Success Stories of

CNC Machining Projects

Why Choose Us

Our ISO-certified CNC machining ensures precision and quality. Every part is made to fit perfectly and perform flawlessly with advanced quality control at every step.

Keep your projects moving with RapidDirect. Our local workshops and advanced equipment provide quick turnarounds to meet your deadlines.

Count on us anytime, anywhere for your CNC machining needs. Our specialists provide support to maximize design efficiency and quality.

Ultimate Guide to CNC Machining

CNC Machining FAQs

CNC machining has a wide range of applications across industries.

- In the automotive and aerospace sectors, it is used to fabricate precise engine components, structural parts, and other intricate elements.

- The medical industry leverages CNC for manufacturing devices, implants, and surgical instruments.

- CNC is also crucial in electronics, enabling the production of electronic housings, circuit boards, and connectors.

- Machine tool makers rely on CNC to create complex molds, dies, and machine components. Additionally,

- CNC is valuable for general custom part production, prototyping, woodworking, and more, allowing for consistent quality and high precision.

Advantages of CNC Machining

- Precision and Repeatability: CNC machining ensures high precision and consistent replication of parts, crucial for complex designs with tight tolerances.

- Reduced Human Error: The automated nature of CNC machining minimizes human error, enhancing the overall quality of production.

- Efficiency and Speed: Automation allows for faster production cycles, enabling quicker turnaround times than manual processes.

- Material Flexibility: CNC machines can work with a diverse range of materials, including metals, plastics, and composites, offering versatility across various applications.

- Software Integration: Advanced CNC software supports quick design changes and updates, facilitating rapid prototyping and easy customization.

- Cost-Effective for Large Runs: While setup costs are higher, per-unit costs decrease significantly with larger production volumes, making it cost-effective for mass production.

Disadvantages of CNC Machining

- High Initial Costs: CNC machinery and its maintenance represent significant investments, making initial setup expensive, especially for small-scale operations.

- Skill Requirements: Operating CNC machines requires highly skilled personnel, which can increase training costs and limit accessibility.

- Less Cost-Effective for Small Runs: Due to setup and programming time, CNC machining may not be economical for producing small quantities of parts.

- Material Waste: CNC machining often involves subtractive processes, leading to more material waste compared to additive manufacturing.

- Limited to Material Hardness: Extremely hard materials can wear out CNC tools quickly, potentially increasing operational costs and downtime.

Manufacturing Process: 3D printing is an additive process, building parts layer by layer from materials like plastic or metal. In contrast, CNC machining is subtractive, cutting away material from a solid block to shape the final product.

Material Efficiency: 3D printing minimizes waste by using only the material needed to form the part, whereas CNC machining can produce more waste due to its subtractive nature.

Speed and Cost: For small batches and complex geometries, 3D printing can be faster and more cost-effective. CNC machining is preferable for larger volumes and materials requiring high precision and strength.

Surface Finish and Tolerances: CNC machining typically achieves better surface finishes and tighter tolerances compared to 3D printing.

John T. Parsons is often credited as the father of CNC machining. In the late 1940s, Parsons developed the first numerical control techniques and applied them to the production of helicopter rotor blades. Working alongside engineer Frank L. Stulen, Parsons conceptualized the method of using punched tape to guide machine tools. This innovation laid the groundwork for the development of CNC (Computer Numerical Control) technology. Their pioneering work eventually led to the creation of the first CNC machines in the 1950s, which revolutionized manufacturing by improving the precision, efficiency, and repeatability of machining processes.

G and M codes are the programming languages used in CNC machining to control CNC machine tools. G-codes are primarily used for specifying the movements of the machine, such as linear interpolation, circular movements, and other specific functions related to the actual path of the tool. M-codes, on the other hand, handle machine functions that are not directly related to the path of the tool, such as turning the machine on or off, starting or stopping the spindle, and controlling coolant. Together, G and M codes provide a comprehensive set of instructions that CNC machines follow to produce parts accurately and efficiently.

CNC machining is renowned for its ability to achieve high precision and tight tolerances, essential for complex and detailed parts. Typically, standard CNC machining can maintain tolerances within ±0.01 inches (±0.127 mm). RapidDirect defaults to standardized tolerances without special requirements. For even more precise requirements, advanced CNC machines can achieve tolerances as tight as ±0.0005 inches (±0.0127 mm) under optimal conditions. The achievable tolerance depends on several factors including the material, part geometry, size, and the specific type of CNC machine used. This capability makes CNC machining a preferred choice for industries that require highly accurate components, such as aerospace, medical, and automotive sectors.

A machining center is a highly advanced CNC machine designed to handle a variety of machining tasks including milling, drilling, and tapping, all within a single setup. This integration enhances efficiency and accuracy by reducing the need to transfer parts between different machines. Machining centers are equipped with a tool turret or magazine that holds multiple tool options, enabling automatic tool changing under CNC control. This capability allows for rapid switching between operations, optimizing production flow. Typically, machining centers are used for complex parts that require precision machining from multiple angles, making them indispensable in modern manufacturing environments.

Certainly! At RapidDirect, we have the capacity to manufacture over 10,000 diverse prototypes each month, ranging from straightforward to complex designs. Our production capabilities are supported by more than 200 state-of-the-art CNC machines. We also take pride in our team of over 100 skilled technical experts who ensure precision and quality in every project. This extensive infrastructure allows us to meet large-scale demands efficiently, making us a reliable partner for all your CNC machining needs. Whether your project is big or small, our resources are geared to deliver with excellence.

The expense associated with our CNC machining service is variable and directly influenced by the distinct attributes of your project, including its design and tolerance specifications. The machining duration for the chosen material is another key determinant of the cost. To illustrate, should you require a part where the combined machining and material expense is $2, with an additional setup charge of $200, the total cost for a singular part would amount to $202. Contrastingly, should you commission the production of 200 identical parts, the cost per unit would be just $3! Learn more about the CNC machining costs.

At RapidDirect, we understand the diverse needs of our customers, ranging from single prototypes to large-scale production runs. Consequently, we do not enforce a strict minimum order quantity (MOQ). Whether you require just one machined part or thousands, we are equipped and ready to provide tailored solutions that meet your specific requirements. Our flexible approach ensures that all clients, regardless of order size, receive the highest level of service and quality.

The lead time for receiving a CNC machined part from RapidDirect can vary depending on several factors including the complexity of the part’s design, the type of material selected, and our current production schedule. CNC machining is known for its speed, particularly for less complex parts, allowing for quick turnaround times. In fact, parts can be delivered in as fast as just one day after the machining setup is complete! However, for the most accurate time estimate tailored to your specific project, we recommend contacting us directly for a detailed quote. This way, we can provide you with a precise timeframe based on your unique requirements.

CNC Machining Resources

Low Volume CNC Machining: Advantages, Applications and Design Tips

What Is Face Milling? Process and Best Practices

now, for free