Top 10 Plastic Resins For Injection Molding

With several advantages over other manufacturing techniques, plastic injection molding has become one of the most popular techniques employed by ...

Provide efficient production and faster design to delivery.

Produce precision parts that exceed industry standards.

Create and test products quickly to bring them to market.

Bring new, affordable products to market faster.

Empower to innovate faster, maximizing performance.

Innovation in enclosures for low-volume production.

Deliver machinery that beats the competition.

Speed up innovation and development.

Build prototypes and products that adhere to medical safety.

Improve efficiency with precise, fast, and constant part quality.

Drive time-to-market through on-demand production.

The extremely high level of precision needed within the aerospace industry makes CNC machining a suitable manufacturing process for the sector.

This article provides you with a complete guide to aerospace machining and its importance.

Improve manufacturing know-how with our eBooks collection.

Learn successful stories to inspire your project.

Select from 30+ surface finishing options.

Choose from 50+ metals and plastics for your project.

If you want to produce high-quality machined parts with a sleek appearance, it’s essential to consider some critical factors related to CNC machining.

Here, we’ve gathered some basic information and important considerations to help you achieve the desired results.

Our vision, mission, development history, and dedicated team.

Get instant quotes with our smart online platform.

Deliver quality parts that meet requirements and exceed expectations.

Exciting news from RapidDirect! We’ve rolled out two exciting updates to enhance your manufacturing journey.

Access top-notch plastic injection molding services for your custom prototypes and production parts. Get injection molded parts with impeccable quality, excellent finishes, and high dimensional stability at competitive prices.

Injection molding is a cost-effective means of getting plastic parts in small and large batches. It is a repeatable process that ensures the delivery of several components with consistent quality. RapidDirect is a world-class plastic injection molding company offering the complete manufacturing solution for your project. With a commitment to customer satisfaction, our custom plastic injection molding services involve on-demand prototyping and production. Get plastic injection molding parts with superior quality, regardless of size and complexity.

RapidDirect provides advanced injection molding services, with solutions covering material verification, tool design, prototyping & production, finishing, and quality assurance. Our team of experts is committed to delivering professional technical support. With precise prototypes and production parts, RapidDirect helps you reach your manufacturing goals.

No minimum order requirement helps move plastic molded parts from design to production in a fast turnaround and supports your on-demand molding manufacturing needs with reduced injection molding cost.

With certified domestic factories and a strong supply chain system, we accelerate the product development cycle and bridge the production of your injection molded parts as fast as possible.

Our plastic injection molding process includes vital design considerations to improve moldability and enhance aesthetic appearance. RapidDirect delivers plastic injection molded parts of varying sizes and complexities. Our standard tolerances are defined by ISO 2768 standards, helping us meet tight tolerance requirements.

Working with our experts having 10+ years of experience in the injection molding industry, efficiently complete a turnaround from prototyping to production.

RapidDirect’s injection molding process includes detailed design analysis and expert mold tooling production. Take advantage of the careful design and manufacture of injection mold tools for your custom plastic parts. We will work with you to review the T1 sample before we begin low-volume production. Each production ends with strict inspection and quality control to ensure your parts meet international standards.

Our online quote platform can help you get an instant quote upon request so that our engineers can deliver the quote within 24 hours to get production started.

Our design for manufacturing review enables us to find any defects or concerns beforehand and provide recommendations for a more feasible design.

Using predictive modeling software allows us to see how the molten material will behave when it enters the mold, allowing for further improvements to the design.

We apply high-quality CNC machining to help construct the injection mold, making sure the mold is ready to be used.

T1 sampling will be delivered for you to review prior to manufacturing plastic parts to ensure precision and quality.

After the trial production phase, we begin batch production to manufacture parts at fast rates to save on time and costs.

We follow international tolerance standards to ensure our parts meet your parameters.

We partner with logistics companies to schedule a timely delivery to your region.

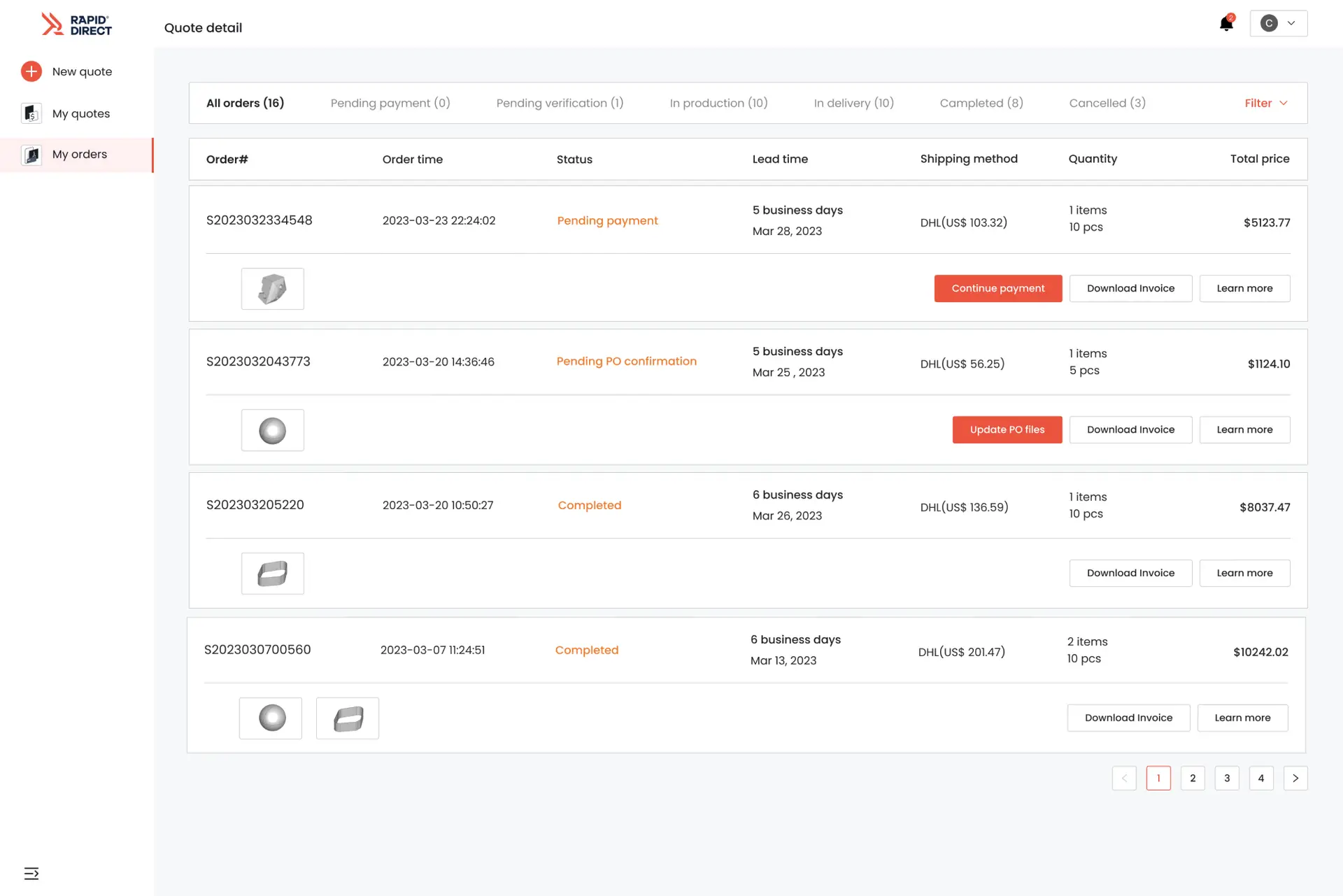

Submit your design files on our online quotation platform to get an instant plastic injection molding quote within 24 hours. Our platform also ensures easy management of your orders; you are in control from quotation to product delivery.

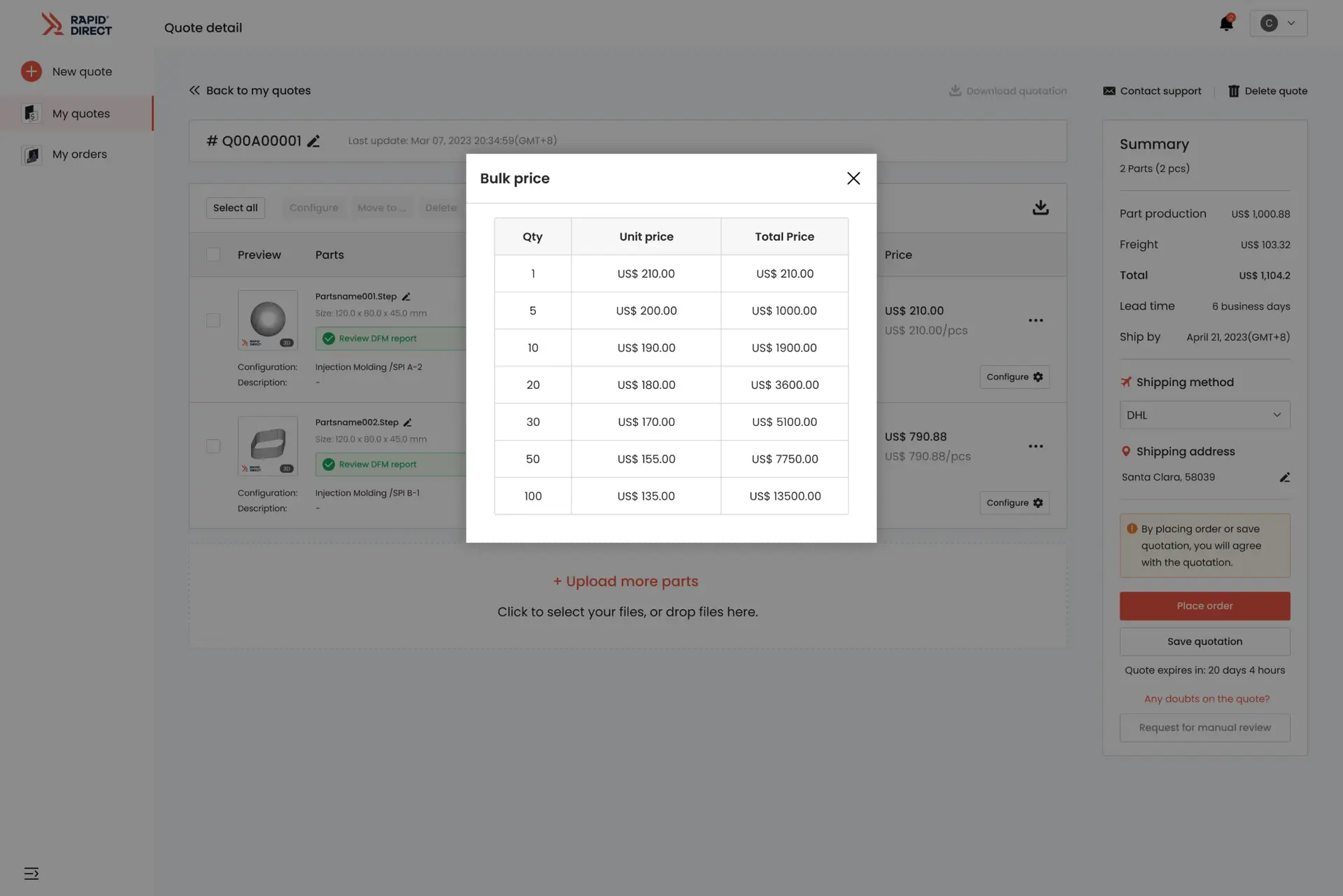

Get in-bulk injection molding quotes, allowing you to make a pricing comparison between different specs, quantities, raw material, and surface finishes, and helping you choose the solution that best suits your needs and budget.

Our online injection molding platform enables real-time visibility of the production flow that fosters more efficient operation monitoring and quicker response to negative changes.

Quickly check, search, and manage all your injection molding orders in one place. What's even better is that you get visibility into all stages of the production process and every aspect of the manufacturing operation.

Get easy design feedback and validation through superior quality prototype tooling. Create small batches of plastic molded parts with excellent injection molding prototypes. We excel at manufacturing prototype molds within days to ensure you perform functional tests and validate market interest.

We create high-quality production molds for high-volume plastic parts production. With high-strength, durable tool steel material, our production tooling is suitable for producing hundreds of thousands of parts. We can vary materials and construction methods according to your unique requirements.

Our plastic injection molding service uses a wide range of plastic, making it suitable for several applications across many industries. As a leading plastic injection molding company, we have over 50 thermoplastics and thermosetting plastics for injection molding. Check out some of the plastic materials you can choose for your parts.

Before injection molding process starts low or high-volume production, a high tolerance CNC machined tooling is needed. Most commonly used materials include:

Tool Steel: P20, H13, S7, NAK80, S136, S136H, 718, 718H, 738

Stainless Steel:

420, NAK80, S136, 316L, 316, 301, 303, 304

Aluminum: 6061, 5052, 7075

Plastic injection molding service comes with a wide range of materials with different properties, including impact strength, rigidity, thermal resistance, chemical resistance, etc.

| ABS | Nylon (PA) | PC | PVC |

| PU | PMMA | PP | PEEK |

| PE | HDPE | PS | POM |

Standard plastic materials may not meet custom injection molding parts requirement. In this case, additives and fibers can be added to improve aesthetic and functional properties, providing additional features for your injection molded parts.

| UV absorbers | Colorants |

| Flame retardants | Glass fibers |

| Plasticizers |

Note: You can learn more from our eBook on plastic materials.

Improve the surface quality of your plastic injection molded parts with superior surface finishing options. RapidDirect provides an extensive list of surface treatments to improve the aesthetic appeal of your products. These efficient secondary operations also improve the mechanical qualities of prototypes and production parts.

Name | Description | Link |

| | Glossy | A grade finishes are made using a diamond buffing process and yield shiny and glossy surfaces on injection molded parts. | Learn More>> |

| | Semi-glossy | B grade finishes use grit sandpaper to produce parts with a slightly rougher finish than grade A parts. Custom molded plastic parts that undergo B grade finishing have a matte surface texture. | |

| | Matte | C grade finishes use grit sanding stones to produce a rough, uneven surface. Injection plastic parts that undergo C grade finishing have a matte surface texture. | Learn More>> |

| | Textured | D grade finishes use grit and dry glass beads or oxide to produce a very rough textured finish. Depending on the type of material used, products can have a satin or dull finish. |

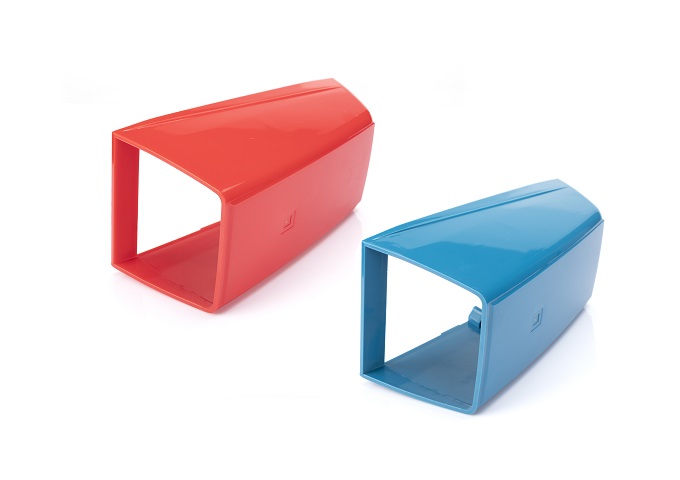

Dive into RapidDirect’s extensive gallery that showcases some of our completed injection molded parts and take confidence that we can create your injection molding project according to your strict specifications.

A customer’s words have a more substantial impact than a company’s claims – and see what our satisfied customers have said regarding how we fulfilled their requirements.

We have been working with RapidDirect for years. They have helped us overcome many mold design issues and have enabled us to meet our quality goals. Their quality systems are really up to par and the production parts have exceeded our expectations.

Keith Laurie

-Tooling Design Engineer

RapidDirect has been our molding partner for over 2 years. Since then, RapidDirect has regularly provided us with top-notch molded parts. In addition, RapidDirect has offered assembly services for various models of our multi-bit screwdrivers up until the final finished product. I am pleased to recommend RapidDirect to anyone looking for top-notch molded products.

Harri Rossi

– Engineer

The staff at RapidDirect has assisted us in turning our ideas into finished parts for several years now. The process from conception to manufacturing has been smooth, thanks to their knowledge, skills, and “can-do” attitude. This is one of our most fruitful business partnerships because of RapidDirect’s emphasis on customer satisfaction.

Jimmy Kowalski

– Lead Mechanical Engineer

RapidDirect has consistently proved to be a top supplier of injection molded parts for our company. They have constantly impressed us with their professionalism, fairness, and reasonable prices. We’ve hired RapidDirect to create molds for us, fix and adapt existing molds to suit our demands, and deliver items that consistently meet or surpass our strict specifications.

Marcel Ransom

– Designer

RapidDirect has been a wonderful and strategic partner for us right from the beginning. They listen to customers and respond with a high level of technical expertise in materials, part design, and process options. This has been and will continue to be a crucial component of our success.

Danny Smajic

– Director of Product Development

RapidDirect’s plastic injection molding service is perfect for addressing the various demands of different industries, including the automotive, medical, and consumer goods fields.

Our mold-making process includes 6 steps:

Step 1: Production arrangement: Determine all of the requirements and arrange the production.

Step 2: DFM report analysis: Provide free but detailed production DFM report for further feasibility analysis.

Step 3: Production the mold: Put the mold into production and provide the Tooling Schedule form for the whole cycle for clients to check the process at any time.

Step 4: Free sample to test: Put the mold into production and provide the Tooling Schedule form for the whole cycle for clients to check the process at any time.

Step 5: Mass production:Client confirms the samples are qualified, then officially proceed with the subsequent production.

Step 6: Mold saving: Production is completed and delivered after quality inspection. Mold will be cleaned and properly stored for the next round of parts production.

Tolerance is very important, and if not correctly specified and controlled, assembling will fail. RapidDirect uses ISO 2068-c standard for injection molding tolerances unless tighter tolerance required.

No minimum order quantity, but the oder pricing will be more competitive if qty is higher.

After you place order, it takes about 35 days for mold designing and making, and more 3-5 days for molded parts production.

Generally, we generate the quote after our platform must have considered several factors, including the size of the component, mold complexity, number of injection cavities, materials, post-processing needs, etc.

With several advantages over other manufacturing techniques, plastic injection molding has become one of the most popular techniques employed by ...

One way of producing durable and reliable medical-grade components that meet FDA standards is through medical injection molding. The process ...

Copyright © 2024 Shenzhen Rapid Direct Co., Ltd. All rights reserved

Copyright © 2023 Shenzhen Rapid Direct Co., Ltd. All rights reserved.