At RapidDirect, we place a strong emphasis on quality control throughout our injection molding process to ensure that every plastic component meets the highest standards of precision and reliability.

Custom Injection Molding Services

Get custom plastic prototypes and end-use production parts. Request for free injection molding quotes today. Receive expert DFM analysis.

- 20% off your first order

- T1 sample as fast as 2 weeks

- No minimums

- ISO 9001:2015, ISO 13485, ISO14001:2015, IATF 16949:2016 certified

Uploading

Max. file size: ≤15MB

Custom Injection Molding Services

Get free injection molding quotes and expert feedback for rapid molds, production tooling and custom molded prototypes in one day. 100+ thermoplastic, thermoset materials available. ISO 9001:2015, ISO 13485, ISO14001:2015, IATF 16949:2016 certified.

Start A New Injection Molding Quote

Plastic Injection Molding Services for

Custom Parts

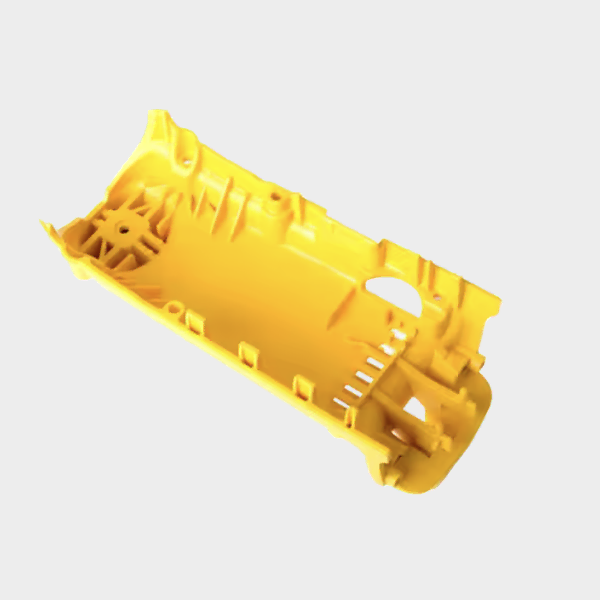

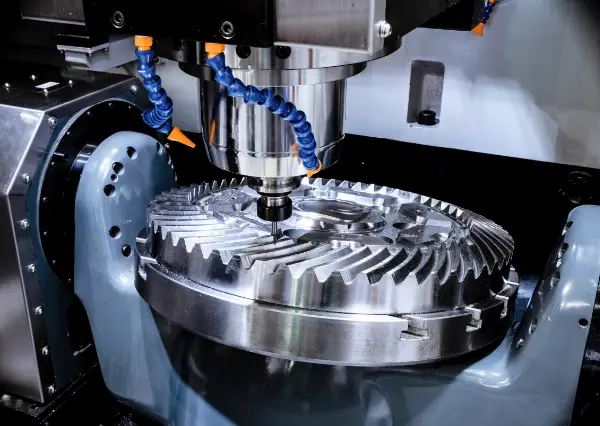

RapidDirect delivers custom injection molding, from on-demand prototypes to production molding. With 90 to 830-ton machines in our China-based facilities, we manufacture high-quality plastic molded parts of any size or complexity. We work with thermoplastics and thermosets, offering ISO 9001-c or tighter tolerances. Get expert guidance on quotes and solutions for a seamless design-to-production process.

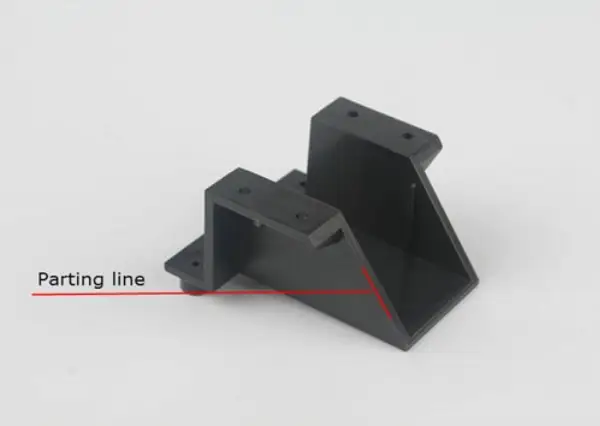

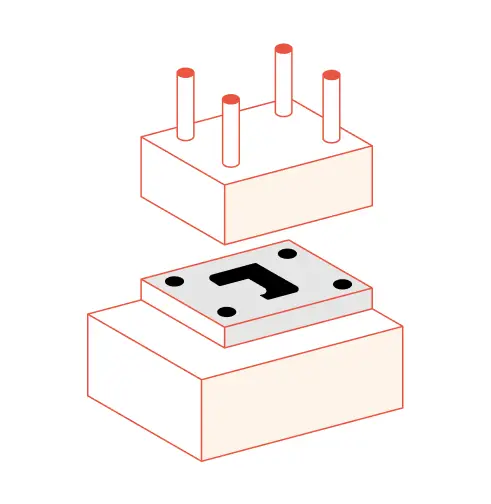

Injection Mold Tooling

Get high-quality aluminum and steel injection molds customized to your needs. We achieve tight tolerances of 0.0008 in (0.02 mm) and offer free mold flow analysis. Ideal for mass production.

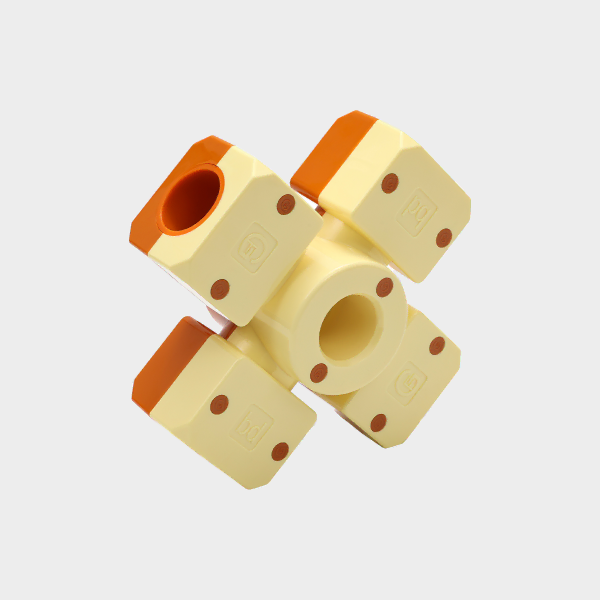

Overmolding

Overmolding is a multi-step injection molding process that bonds plastic to another component (substrate), creating an integrated, durable product. Offers color and texture options.

Insert Molding

A subset of injection molding techniques where combines engineering plastics with pre-placed inserts in the mold cavity. It eliminates the need for fasteners.

Injection Molding

Manufacturing Network

With over 50 advanced machines handling up to 830 tons, our network efficiently manages projects from prototypes to full-scale production. Every project begins with a detailed injection mold quote for clear expectations. Our expert project managers provide in-depth manufacturing analysis and consultative design services to optimize cost and functionality. The process ends with thorough quality reports, ensuring all components exceed industry standards.

50+

Machines Set

120+

Countries Shipped

20,000+

Customers Served

Injection Molding Materials

We offer a broad range of thermoplastic and thermoset materials, each selected for its performance characteristics and suitability for different applications.

ABS

Strong, durable, and impact-resistant, ABS offers excellent heat resistance and is commonly used in automotive parts, consumer electronics, and household goods. Its toughness and versatility make it a popular choice for high-demand applications.

| Color: | Beige Black White |

| Subtypes: | ABS Beige (Natural), ABS Black, ABS Black Antistatic, ABS Milky White, ABS+PC Black, Flame Retardant ABS Beige, Flame Retardant ABS Black. |

| Price: | $$ |

| Lead Time: | About 5 business days |

PC

Known for its exceptional strength and high impact resistance, polycarbonate also boasts excellent transparency. It’s used in safety-critical applications like bulletproof glass, eyewear lenses, and protective gear, where clarity and durability are key.

| Color: | White Black |

| Subtypes: | Flame Retardant Transparent PC, Food Grade PC-Transparent, PC Black, PC Transparent, PC White, PC Yellowish White, PC+GF30 Black |

| Price: | $$ |

| Lead Time: | About 5 business days |

PMMA (Acrylic)

With its crystal-clear appearance and outstanding weather resistance, PMMA is ideal for outdoor displays, signage, and lighting. It’s more durable than glass and can withstand UV exposure without degrading over time.

| Color: | Black White |

| Subtypes: | PMMA Black, PMMA Transparent, PMMA White |

| Price: | $ |

| Lead Time: | About 5 business days |

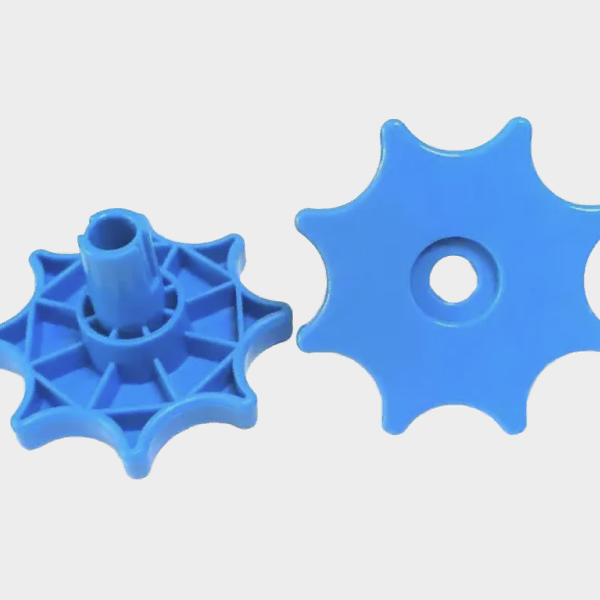

POM

POM is a high-performance plastic with excellent dimensional stability, low friction, and high strength. It's commonly used in precision mechanical components like gears, bearings, and other high-stress parts where accuracy is critical.

| Color: | Black White Blue Dark brown |

| Subtypes: | Dark Brown (Coffee) POM 100AF, POM Black, POM Blue, POM White |

| Price: | $$ |

| Lead Time: | About 5 business days |

PA (Nylon)

Known for its strength, flexibility, and wear resistance, nylon is used in a wide range of industrial applications, including gears, bearings, and automotive components. It also has good resistance to abrasion and friction.

| Color: | Blue Black Beige |

| Subtypes: | PA(Nylon) Blue, PA6 (Nylon)+GF15 Black, PA6 (Nylon)+GF30 Black, PA66 (Nylon) Beige(Natural), PA66 (Nylon) Black |

| Price: | $$ |

| Lead Time: | About 5 business days |

PE

Lightweight, tough, and resistant to impact, polyethylene is a versatile material used in packaging, containers, and piping. Its chemical resistance and durability make it ideal for outdoor and high-moisture environments.

| Color: | Black White |

| Subtypes: | PE Black, PE White |

| Price: | $$ |

| Lead Time: | About 5 business days |

PEEK

Renowned for its exceptional heat resistance, mechanical strength, and chemical resistance, PEEK is commonly used in aerospace, automotive, and medical implant applications, where high performance at extreme temperatures is required.

| Color: | Beige Black |

| Subtypes: | PEEK Beige (Natural) and PEEK Black |

| Price: | $$$ |

| Lead Time: | About 5 business days |

PP

Tough, chemically resistant, and lightweight, polypropylene is widely used in automotive parts, packaging, and medical devices. Its resistance to chemicals and low moisture absorption makes it suitable for many industrial applications.

| Color: | Black White |

| Subtypes: | PP Black, PP White, PP+GF30 Black |

| Price: | $ |

| Lead Time: | About 5 business days |

HDPE

High-density polyethylene offers excellent strength-to-density ratio, impact resistance, and durability. It’s used in manufacturing bottles, corrosion-resistant piping, and plastic lumber due to its resilience in harsh environments.

| Color: | Black White |

| Subtypes: | HDPE Black, HDPE White |

| Price: | $$ |

| Lead Time: | About 5 business days |

HIPS

High-impact polystyrene is easy to process and machine, offering good impact resistance and dimensional stability. It's frequently used in prototyping, displays, and packaging due to its ease of molding and processing.

| Color: | White |

| Subtypes: | HIPS Board White |

| Price: | $$ |

| Lead Time: | About 5 business days |

LDPE

Soft, flexible, and with excellent sealing properties, LDPE is commonly used in plastic bags, tubing, and films. Its flexibility and ease of processing make it ideal for applications requiring heat sealing or stretchability.

| Color: | White |

| Subtypes: | LDPE White |

| Price: | $$ |

| Lead Time: | About 5 business days |

PBT

PBT is a rigid, heat-resistant material known for its strength and dimensional stability. It's widely used in automotive, electrical, and electronics applications, including connectors and casings.

| Color: | Black Milky White |

| Subtypes: | PBT Black, PBT Milky White(Natural) |

| Price: | $$ |

| Lead Time: | About 5 business days |

PET

Strong, chemical-resistant, and moisture-resistant, PET is used in a variety of applications, including food containers, beverage bottles, and textiles. Its high strength and recyclability make it a popular choice in packaging.

| Color: | Black White |

| Subtypes: | PET Black, PET White, PET+GF30 Black, PET+GF30 White |

| Price: | $ |

| Lead Time: | About 5 business days |

PPS

PPS provides excellent chemical resistance and heat stability, making it ideal for use in automotive, aerospace, and industrial applications. It's used for components exposed to high temperatures and harsh chemicals.

| Color: | Black White |

| Subtypes: | PPS Black, PPS White, PPS+GF30 Black, PPS+GF30 White |

| Price: | $$ |

| Lead Time: | About 5 business days |

PS

Lightweight and easy to machine, PS is often used for models, prototypes, and low-strength applications. Its ability to be easily molded makes it a preferred material in packaging and disposable items.

| Color: | Transparent |

| Subtypes: | PS Transparent |

| Price: | $$ |

| Lead Time: | About 5 business days |

PVC

PVC is a versatile, cost-effective material with good chemical resistance and durability. It's widely used in plumbing, medical devices, electrical cables, and construction materials due to its strength and versatility.

| Color: | Grey |

| Subtypes: | PVC Grey |

| Price: | $$ |

| Lead Time: | About 5 business days |

PTFE (Teflon)

Known for its excellent chemical resistance and low friction properties, PTFE is commonly used in non-stick coatings, gaskets, seals, and bearings. It performs well in extreme environments, with high temperatures and aggressive chemicals.

| Color: | Black White |

| Subtypes: | Teflon (PTFE) Black, Teflon (PTFE) White |

| Price: | $ |

| Lead Time: | About 5 business days |

UPE

UPE is a tough, durable material with outstanding abrasion resistance. It's typically used in high-wear applications such as lining chutes, hoppers, and conveyor systems where impact resistance is crucial.

| Color: | Black White |

| Subtypes: | UPE Black, UPE White |

| Price: | $$ |

| Lead Time: | About 5 business days |

Injection Mold

Surface Finishes

At RapidDirect, we offer SPI surface finishes for injection molded parts. Our injection molding expert is here to help you choose the right finish for your project. Upload your design on our quoting platform today and receive a detailed quote within 24 hours.

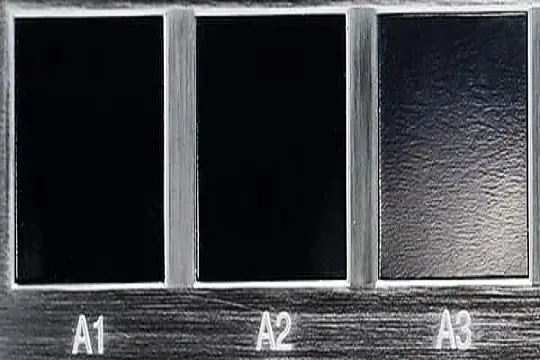

SPI A

| Finishing Look | High Gloss |

|---|---|

| SPI Finish Grades | SPI A1, A2, A3 |

| Surface Roughness Ra (μm) | SPIA1: 0.012 to 0.025 SPIA2: 0.012 to 0.025 SPIA3: 0.05 to 0.10 |

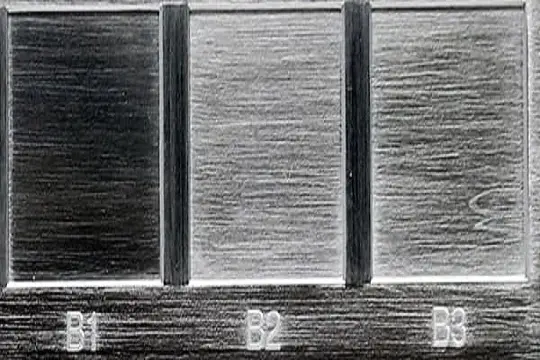

SPI B

| Finishing Look | Semi Gloss |

|---|---|

| SPI Finish Grades | SPI B1, B2, B3 |

| Surface Roughness Ra (μm) | SPI B1: 0.05 to 0.10 SPI B2: 0.10 to 0.15 SPI B3: 0.28 to 0.32 |

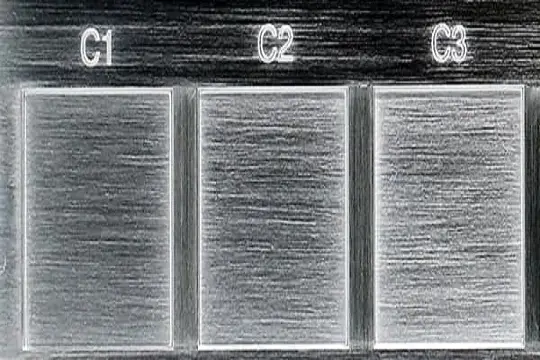

SPI C

| Finishing Look | Low Gloss |

|---|---|

| SPI Finish Grades | SPI C1, C2, C3 |

| Surface Roughness Ra (μm) | SPI C1: 0.35 to 0.40 SPI C2: 0.45 to 0.55 SPI C3: 0.63 to 0.70 |

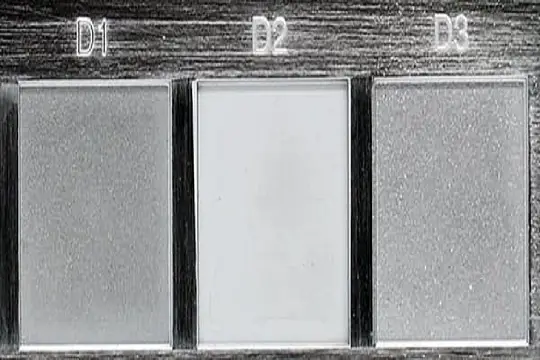

SPI D

| Finishing Look | Matte |

|---|---|

| SPI Finish Grades | SPI D1, D2, D3 |

| Surface Roughness Ra (μm) | SPI D1: 0.80 to 1.00 SPI D2: 1.00 to 2.80 SPI D3: 3.20 to 18.0 |

Injection Molding Capabilities

| Standards | Description |

|---|---|

| Maximum Part Size | 1200×1000×500 mm |

| Manimum Part Size | 5×5×5 mm |

| Part to Part Repeatability | +/- 0.1 mm |

| Mold Cavities | Single-cavity molds, multi-cavity molds, family molds |

| Available Mold Types | Steel and aluminum molds. Production levels below 1000, 5000, 30000, and over 100000 uses |

| Mold Cavity Tolerances | +/- 0.02 mm |

| Secondary Operations | Mold texturing, pad printing, laser engraving, threaded inserts, and basic assembly |

| Undercuts | Y-type, L-type undercuts |

| Wall Thickness | 0.5 mm to 5 mm |

| Draft | 0.5° to 2° |

| Ribs/Gussets | 0.5 mm to 3 mm thick |

| Bosses | Diameter 3 mm to 10 mm |

| Lead Time | Most orders can be completed within 15 working days |

Injection Molding Design Guide

Having a thorough understanding of the injection molding design guide is essential to achieving outstanding results.

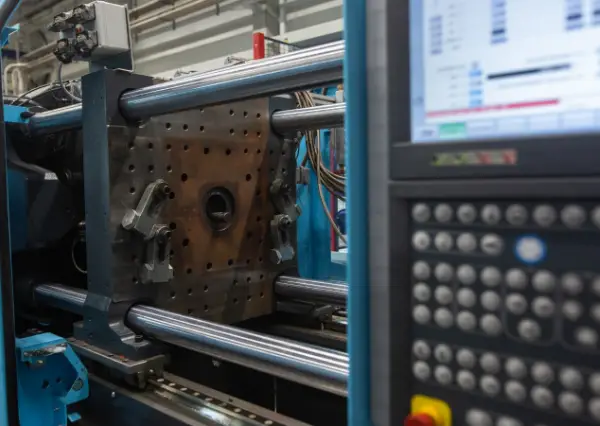

How Does RapidDirect Injection Molding Process Work

At RapidDirect, we streamline your order process—from online quotes to high-quality mold making and production-ready plastic parts. Our expert team and state-of-the-art machinery guarantee efficiency and timely delivery.

/01 Upload Design File

/02 Get Quote with DFM

/03 Review T1 Sample

/04 Production Begins

/05 Delivery

/06 Ready to Start

RapidDirect

Injection Molding Solutions

Get custom plastic prototypes and production parts with flexible solutions from RapidDirect.

Rapid Prototyping

Address critical time-to-market needs by providing flexibility and economic efficiency for iterative development before full-scale production.

- Utilize aluminum or steel molds, which are perfect for rigorous testing and iterative processes.

- Typically single cavity, allowing for precise control during the prototype phase.

- Efficiently produce anything from a single unit to small batches (up to 2,000 units), facilitating quick market testing and design validation.

High-Volume Production

Support large-scale manufacturing demands, effectively overcoming common production challenges and offering on-demand production capabilities.

- Durable steel molds designed for high repeatability across extensive production runs.

- Available in single or multi-cavity configurations to optimize productivity and cost-efficiency.

- Ability to scale production seamlessly to meet large order demands, ensuring consistent quality and timely delivery.

Prototyping Injection Molding

- Quantity: 1-100 pcs

- Lead Time: 1-3 weeks

- Soft tooling or 3D-printed mold used

Low Volume Injection Molding

Quantity: 100-10,000 pcs

Lead Time: 3-6 weeks

Mass Production

RapidDirect’s high-volume injection molding offers a fast, cost-effective way to mass-produce precise, identical parts. With advanced equipment and strict quality control, we ensure tight tolerances and consistent quality across a variety of plastic materials for your specific needs.

- Quantity: Over 10,000 pcs, can go into the millions

- Lead Time: 4-12 weeks or more

- 100+ thermoplastic, thermoset materials available

Trusted Experts in Plastic Molding Solutions

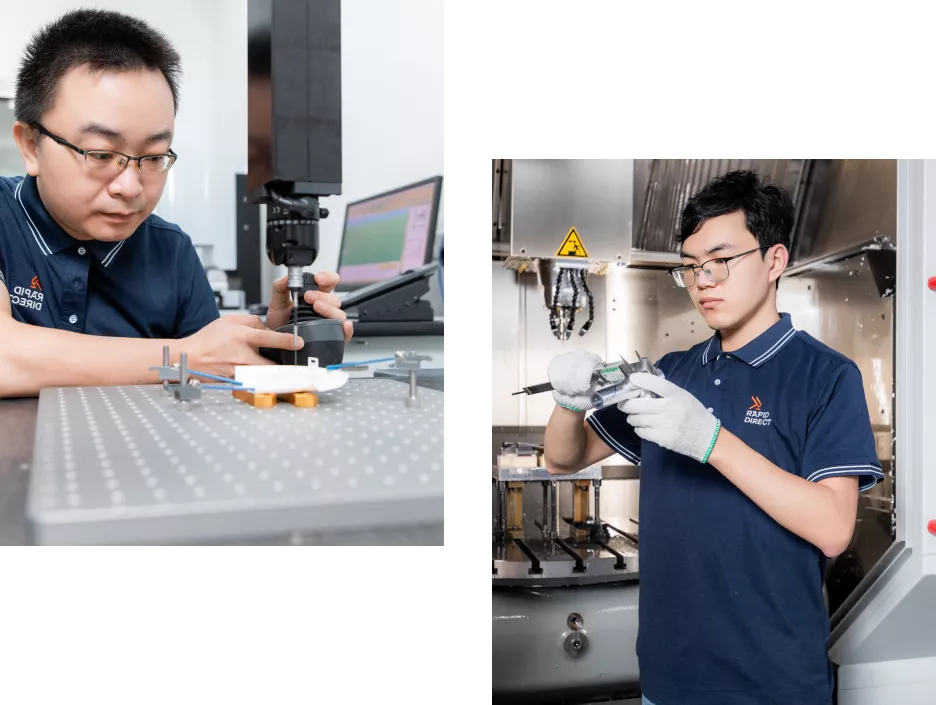

The first stage of quality control begins with a comprehensive design review. Our team provides detailedDFM feedback, helping to optimize your design for moldability and reduce potential production issues.

During production, we implement robust in-process quality control measures. From inspecting incoming raw materials to final product checks, our skilled operators and technicians monitor and refine every step to maintain consistency and accuracy. We use advanced inspection tools, such as CMM, XRF analyzers, and micrometers, to ensure precision.

With our ISO 9001:2015 certification and commitment to excellence, , we ensure that every part leaving our facility upholds the highest standards of quality and reliability.

- 20+ inspection equipment

- 30+ quality engineers

- ISO 9001:2015, ISO 13485, ISO 14001, and IATF 16949

Injection Molding

Timeline

Looking to optimize your injection molding process? Grab our comprehensive timeline Gantt chart to monitor your project’s progress, ensuring adherence to budget and specifications.

Injection Molding

for Various Industries

From automotive to electronics, RapidDirect’s injection molding services deliver reliable, cost-effective solutions to fit the custom demands of each industry.

Why

Choose Us

Our ISO-certified factories do in-process checks and post-production tests to make sure every custom molded part is precise and consistent, no matter how complex.

We use certified local factories and a strong supply chain to speed up product development, delivering plastic parts in as little as 2 weeks.

Talk to our experts with 10+ years of experience in injection molding for help with mold design, material selection, and finishes—making the whole process smoother.

Applications of Injection Molding

Injection molding is huge in making a ton of products—anything from car parts to medical devices. It’s super efficient because it can produce lots of identical plastic parts with tight tolerances, all at a low cost per part. That’s why so many industries rely on it for mass production. Whether it’s a simple or complex design, it keeps quality high and production fast.

- Gears: High-tolerance, durable gears for mechanical and electronic devices.

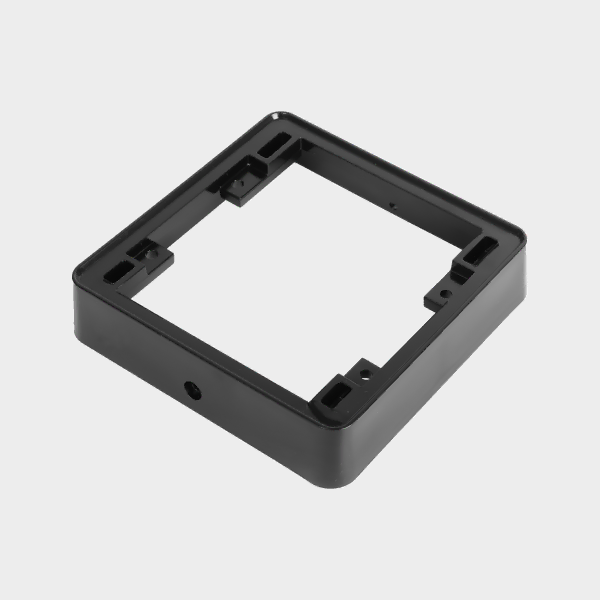

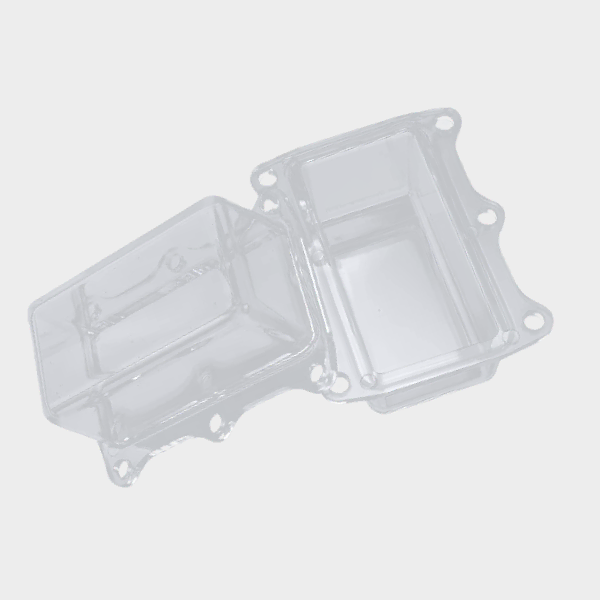

- Housings: Strong housings for electronics, automotive parts, and industrial machines.

- Enclosures: Precise enclosures for electronics, protecting internal components.

- Handles: Ergonomic, durable handles for tools, appliances, and products.

- Caps and Closures: Efficient caps and closures for bottles, ensuring tight seals.

- Connectors: Small, intricate connectors for electrical and electronic needs.

Advantages of Injection Molding

Injection molding is key when you need to make complex parts with perfect consistency. It’s built for high-volume production, turning out millions of identical plastic parts with great precision. The setup costs can be high, but once it’s running, you can produce parts fast and at a low cost per unit. Plus, it works with a variety of materials, including plastics and liquid silicone rubber, which is why it’s the go-to for most plastic products on the market.

Disadvantagess of Injection Molding

Plastic injection molding has a lot of perks, like being great for mass-producing complex parts, but it’s not without its downsides. The main issues are high initial costs, long lead times, design limitations, and it’s not cost-effective for small production runs. If these factors are a big deal for your project, you might want to consider alternatives like 3D printing or CNC machining, which could be a better fit depending on your needs.

FAQs

Injection molding is a manufacturing process used to produce parts by injecting molten material into a mold. It is commonly used with plastics but can also accommodate metals, glasses, and elastomers. The process begins with melting the material, which is then injected under pressure into a mold cavity. Once the material cools and solidifies, the mold is opened to eject the finished part. This technique is favored for its ability to produce large volumes of identical parts with high precision, complex shapes, and excellent surface finish. Injection molding is efficient and cost-effective, particularly suitable for mass production.

Injection molding is a complex process that involves four key stages to create high-quality plastic parts:

- Clamping: Before the injection of the material, the two halves of the mold must be securely clamped together by the injection molding machine. This is crucial to prevent the mold from opening during injection, ensuring that the molten plastic does not escape.

- Injection: Molten plastic is injected into the clamped mold at high pressure. This stage involves packing the plastic into the mold and maintaining pressure to fill every part of the mold cavity completely.

- Cooling: After the mold is filled, the plastic begins to cool and solidify within the mold’s cavities. The cooling must be controlled to prevent defects and ensure that the part maintains proper dimensions and mechanical properties.

- Ejection: Once the part has cooled and solidified, the mold opens and an ejection mechanism pushes the completed part out of the mold. The machine is then ready to start a new cycle with the clamping of the mold for the next part.

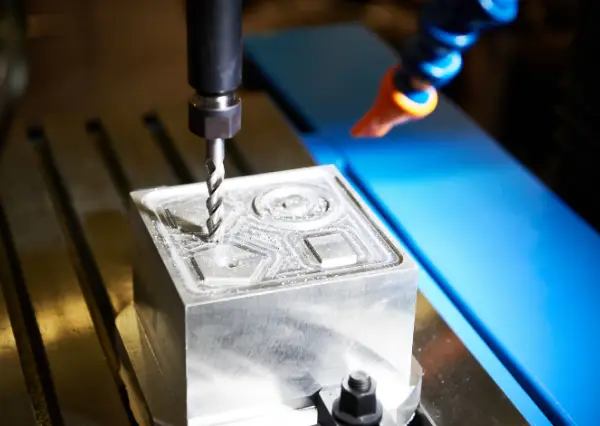

Our injection mold-making process includes six essential steps:

Step 1: Production Arrangement: We begin by thoroughly understanding all requirements and arranging the production details accordingly.

Step 2: DFM Report Analysis: A detailed Design for Manufacturability (DFM) report is provided free of charge. This report helps in conducting a feasibility analysis to ensure the mold will meet all specifications and quality standards.

Step 3: Production of the Mold: The mold is put into production. We provide clients with a Tooling Schedule form that outlines the entire cycle, allowing them to track the progress at any time.

Step 4: Free Sample Testing: Once the mold is produced, a sample is created and provided to the client for testing to ensure it meets the required specifications.

Step 5: Mass Production: Upon client confirmation that the sample meets all quality and functionality criteria, full-scale production commences.

Step 6: Mold Saving: After production and a thorough quality inspection, the parts are delivered. The mold is then cleaned and properly stored to maintain its condition for future production runs.

In injection molding, maintaining precise tolerances is essential to ensure that parts fit correctly and function as intended, avoiding potential assembly issues. At RapidDirect, we strictly adhere to the ISO 2768-c standard for general tolerances, which is commonly used across the industry for molded parts. This standard provides a range of tolerances for different features and dimensions, ensuring consistency and reliability in production. For projects requiring even stricter tolerances, we have the capability to accommodate tighter specifications, based on the unique requirements of each client’s application. This flexibility allows us to deliver precisely engineered parts that meet or exceed all expectations.

At RapidDirect, we understand the diverse needs of our clients, which is why we have no minimum order requirement for our injection molding services. This flexibility allows businesses of all sizes to access high-quality molded parts, regardless of the size of their project. While we are equipped to handle orders from a single prototype to thousands of units, it’s worth noting that larger order quantities typically result in more competitive pricing. This volume discount is due to the economies of scale in production, making larger orders more cost-effective per unit. Whether your project is large or small, we are here to provide the best value and service.

The cost of our injection molding services varies depending on multiple factors, including the size of the component, mold complexity, number of cavities, material type, and any specific post-processing requirements. Each project is unique, and we provide personalized quotes to ensure that you receive a detailed cost assessment tailored to your specific needs. This transparent pricing approach allows you to understand the financial implications before committing to the process. To get an accurate estimate, simply upload your project details on our platform, and we will analyze these factors to provide you with a comprehensive quote.

Absolutely, RapidDirect strongly supports the development process by offering rapid prototyping services. This crucial step allows you to test and verify your designs effectively before moving into large-scale production. Prototyping is essential to identify potential issues and ensure that the design meets all functional and aesthetic requirements. By taking advantage of our prototyping services, you can make necessary adjustments early in the development cycle, saving time and costs in later stages. This approach not only enhances product quality but also ensures that the transition to full-scale production is smooth and efficient.

Injection Molding

Resources

Injection Molding

Resources

Types of Valve Gate for Injection Molding

What are the Components of an Injection Mold? All Details

now, for free